Sandvik Coromant CoroMill 745 Face Milling Cutter Provides Higher Metal Removal Rates for Roughing and Semi-Finishing Milling Operations

Cutting tool and tooling system specialist Sandvik Coromant has unveiled a new, high-feed version of the CoroMill 745 face milling cutter, featuring a 25 degree entering angle for additional productivity gains when milling steel and cast iron workpieces. The new high-feed version facilitates even higher metal removal rates (MRR) in applications with depths of cut up to 2.8 mm (0.110 inch). The new cutter is set to benefit sectors such as die and mold, pump and valve, oil and gas, automotive, power generation and general engineering.

Despite the elevated MRR and productivity, there is no compromise to surface finish when using the new high-feed CoroMill 745. A light cutting action from the innovative insert positioning provides excellent chip formation, a smooth, soft sound and low power consumption.

"An important benefit of the new cutter is low cost per edge from its double-sided, 14-edge insert design," says Matts Westin, product manager, Sandvik Coromant. "In fact, purchasing departments will be pleased to learn that tool inventory costs are reduced because the CoroMill 745 with a 25 degree entering angle uses the same inserts as its counterpart cutter with a 42 degree entering angle."

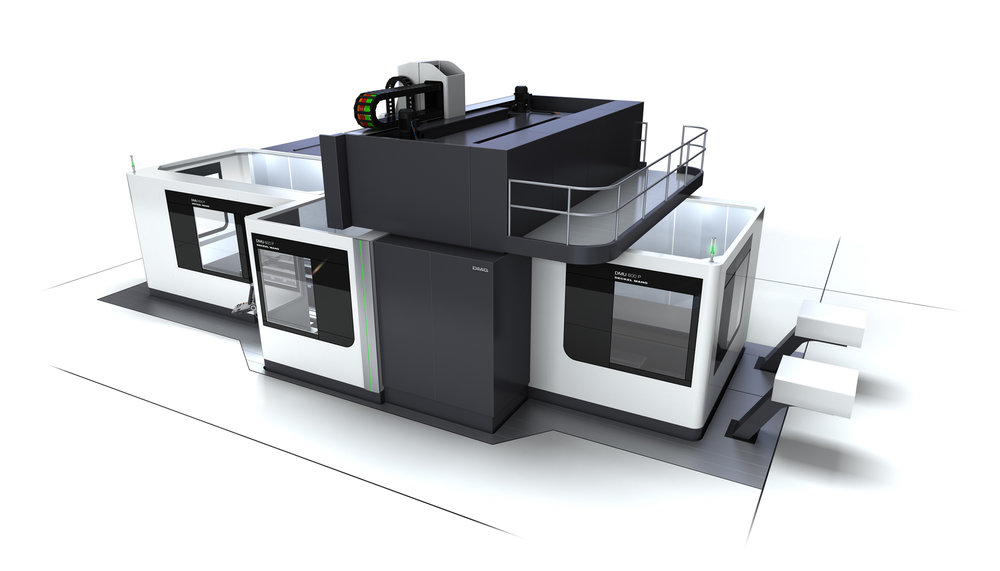

The high-feed CoroMill 745 is aimed at roughing to semi-finishing face milling operations on machining centers and multi-task machines. With its multi-edge concept, the tool is particularly suitable for large batch production, flexible transfer lines and when maximum tool utilization is important. Advantages will be provided when milling components made from ISO P or ISO K materials, such as valves, engine blocks, hubs, main frames, pump components and molds, or any type of general engineering component. The presence of a short (0.6 mm, 0.024 inch) parallel land ensures a good surface finish. The large screw ensures easy handling, while the insert position and the heptagonal insert shape make clamping exceptionally secure for reliable face milling operations. Internal coolant is available for all cutters that range from 63 to 160 mm (2.5 to 6 inches).

Providing an example of the potential gains on the offer, a customer trial application showed impressive benefits when face milling a machine bed component made from cast CMC ST52 (165 HB) on an ISO 50 gantry mill. A 125 mm (5 inch) CoroMill 745 with a 25 degree entering angle reduced cycle time per component by 40 percent in comparison with a competitor tool.

The high-feed CoroMill 745 with a 25 degree entering angle complements the CoroMill 745 with a 42 degree entering angle.