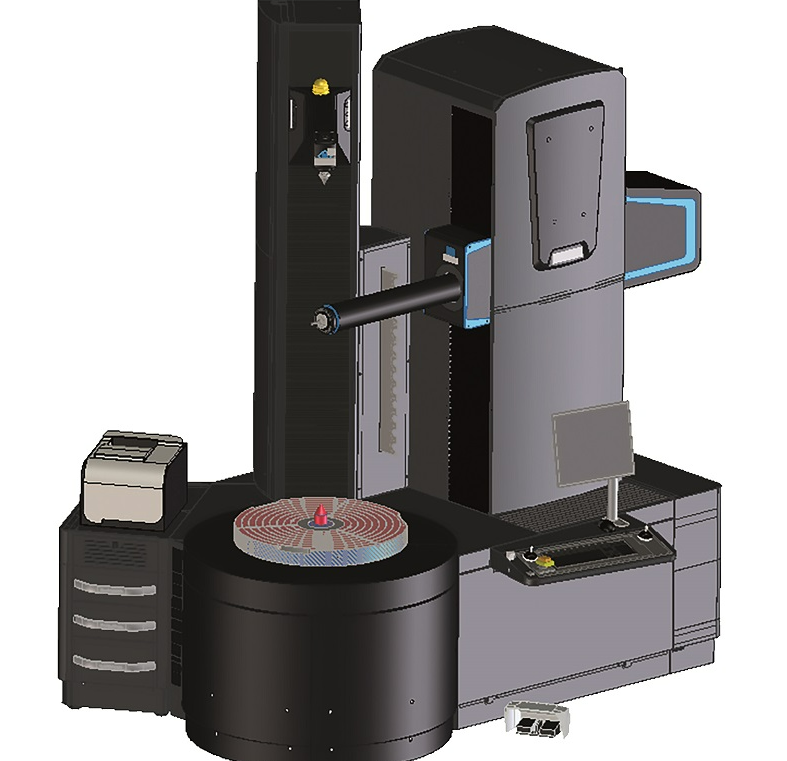

Klingelnberg P 152 Latest Addition to Measuring Center Family

The increasing cost pressure on large components for wind power requires new technologies that will enable proven principles for high-volume and mass production of smaller components to be transferred over to large components. To meet this need, Klingelnberg has developed a new precision measuring center. The P 152 is the latest addition to the family of Klingelnberg precision measuring centers. It is capable of measuring components with a maximum outside diameter of 1,520 mm and workpiece weights up to 8,000 kg with the usual precision. Despite this high workpiece weight, no special foundation is required because the Klingelnberg design engineers succeeded in extending the machine concept of the small and medium series to the large component dimensions. The inherently rigid machine bed with a 3-point support plays a key role here. The bed design and floor support have been so cleverly selected that even when loaded with workpiece weights of up to 8,000 kg, the angular position of the individual machine axes to each other does not change significantly. With its broad range of varied workpiece diameters and measurement tasks, this measuring device is also ideal for contract gear manufacturers. This ensures high precision across the entire component spectrum from smaller to larger gears, and also dimension and form measurements. The 3-point support enables the integration of an active vibration platform into the machine bed. This means that even the low-frequency vibrations from the shop floor can be safely absorbed.

Because the machine is isolated from these vibrations, the P 152 can be located on the normal shop floor without having to build an inherently vibration-isolated foundation. Despite this, it is ensured that all changes visible in the measuring results do come from the component and are not induced by the ambient conditions. The P 152 thus acts as a bridge for medium-sized gears such as planetary gears used in wind power and combines dimension, form, and position measurements with gear measurement, making the operating principles used in high-volume and mass production applicable to large gears as well. Form measurements, such as roundness and cylindricity measurements, are becoming increasingly important on machine elements. The P 152 offers all the possibilities of the Done-in-One principle in the mid-sized diameter range as well.