Customize Gear Skiving for Precise, Efficient Gear Cutting

February 16, 2024

My first mentor was Claude Lutz. He dazzled me switching languages from English to German to French and back to English with such an ease that it gave me hope that perhaps one day I would also be able to acquire a better command of English. Despite the fact that my ability to communicate in English was extremely limited, Claude Lutz hired me as a tool designer in January 1980 after my young family and I were lucky to escape the “socialist paradise” of the Soviet Union. That was the beginning of my 13-year career with the American Pfauter. Claude was also a gear guru and a ski enthusiast. Once Claude asked me to organize a collection of some gear standards. That fleeting project revealed to me a “hidden” wealth of the gear knowledge. The standards became my invaluable reference resource - concise and with comprehensive math background. For example, I would recommend to every aspiring gear engineer reading the seemingly timeless gear fundamentals standard DIN 3960. Its beauty is in its brevity.

After about a year designing fixture and automation for hobbing machines, Claude entrusted me with applications engineering work - reviewing customer drawings and making gear manufacturing and metrology proposals. Claude initiated my transition into the application engineering by giving me a half-hour course on the gear geometry & involute generation by the hobbing method that completely confused me, but luckily for me he did not get discouraged.

Thanks to David Goodfellow’s leadership, in the first half of 1980s, in addition to Pfauter hobbing machines, the American Pfauter picked up representation of a large variety of gear technologies: Hoefler Gear inspection machines, Hoefler Gear grinding machines, Kapp Hob Sharpening and Hob Checking machines followed by Kapp Form Gear Grinding technologies, Lorenz shaping machines, Sicmat Shaving machines, Saazor cutting tools, and more. The companies we represented exposed us to a plethora of new gearing ideas, inventions, solutions for involute generation challenges, and perspectives into the art of gear making. It felt as a proverbial being a kid in a candy store.

Sometime around 1986, the American Pfauter picked up representation of Maag gear cutting, grinding, inspection machines, and cutting tools. While Maag CNC Gear Measuring Centers were of great quality, they had no software capabilities beyond gear inspection. One time while riding in a car together, I suggested to Dave Goodfellow that we could develop more software for Maag Gear Measuring Centers SP42/65 here in the USA. Soon after, Dave entrusted me with leading the team of five people, including three software engineers from Maag, to develop software for automatic hob inspection, followed by reverse gear engineering, worm inspection, involute and non-involute spline, circular geometry, SPC, and more.

I was not the only beneficiary of David Goodfellow’s leadership. During his tenure as president of the American Pfauter, a lot of people took advantage of the fertile environment for learning, blossomed, and became experts in the field of gear technology whether they stayed later with Gleason or move on to notable carriers elsewhere.

One of the inspiring leadership lessons I learned from David Goodfellow was that empowering employees - giving them an opportunity to learn, entrusting them with challenging goals, and providing a lot of freedom to create - benefits both the company and employees.

Brian Cluff, Dennis Gimpert, and Geoff Ashcroft were the American Pfauter sales managers and first instructors at the American Pfauter gear school. Although each one of them has a unique style and unique character, they have in common a deep knowledge of the gear art as well as entertaining qualities that made the gear school successful. They also became my early mentors. One of the important lessons I learned from them was that customers very much value the gear education opportunity beyond the bare-bone machine operator training. Brian Cluff championed the American Pfauter gear school and became the chief editor of the Gear Process Dynamics book. Geoffrey Ashcroft, together with his partners, went on to found the Gear Consulting Group that with AGMA partnership has been providing the Basic Gear Training to gear manufacturers. Dennis Gimpert went on to found Koepfer America that, in addition to the machine tools, offers regular gear schools to their customers and to the gear manufacturers at large.

It is impossible to talk about the American Pfauter without mentioning the legendary George Rieder who was so passionate about the hobbing machines that he would harshly scold anyone, not even sparing customers, who did not treat the machines with the proper care and respect. So, it was a great honor for me when George invited me to visit his extended family in Germany during one of our Pfauter visits.

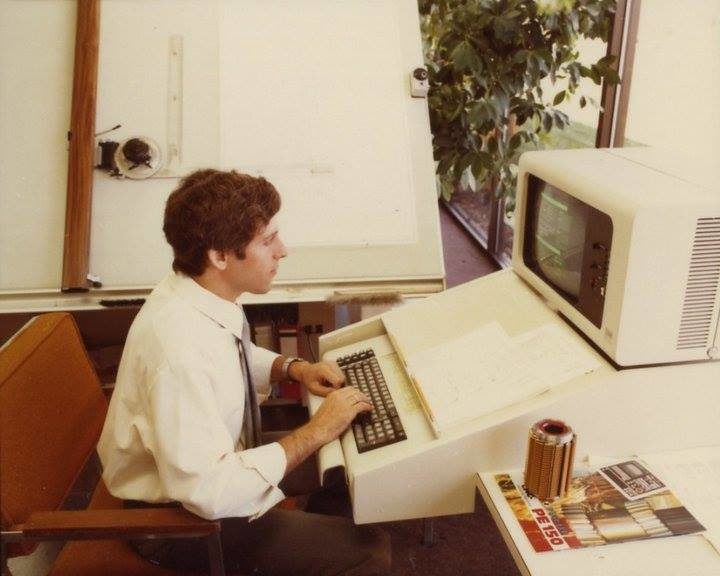

My associate, business partner, a good friend, and a mentor, Ed Driscoll, made a great contribution to the gear industry despite the fact that he knew very little about gears. His experience prior Pfauter was developing computer programs for accounting, financial, and data processing applications. Ed showed up on the American Pfauter scene in the early 80s, when Leon Meuch first acquired computers: IBM System 34 followed by IBM System 36. In a short while after the computer acquisition, Ingrid Chickerling and Leon Meuch, our kind accounting and finance leaders let engineers come a little closer to the computer terminal. One day, I asked Ed Driscoll if he could help me turn a hobbing calculation algorithm into a computer program. No problem, responded Ed and shortly after we had our mainframe predecessor to the Hobtime program.

That was the beginning of our collaboration for many years. Ed and I complemented each other and made a great team at Pfauter and beyond when we went on to develop many gearing, hobbing, cutting tools, and metrology applications together. I admired Ed’s relentless drive to minimize his code, improve its structure and organization. Ed, on the other hand, fully relied on my math models and gear technology algorithms. Ed Driscoll mentored and inspired me as the most resourceful, creative, humorous, and a delight to work with computer genius.

These are just a few short evocations from the early years of my career. But, once again I must acknowledged that there were many more people who inspired and influenced me whether they were brilliant young (some were younger than my children) engineers at Navistar, customers, suppliers, uniquely knowledgeable and generous engineers who volunteer their time for developing AGMA standards, or Italian, German, and Swiss engineers I had an honor to meet.

After forty years working in the gear industry, I still get excited when I learn something new, or meet people who are passionate about their work, and feel fortunate to be connected with this great worldwide gear business and academic community.

Yefim Kotlyar is the Application Engineering Manager at Machine Tool Builders (MTB), responsible for the development of new gear manufacturing and gear metrology technologies. His broad experience in the art of gearing includes the development of various gear cutting technologies, analytical inspection and evaluation technologies for gears and hobs, as well as gear system design and validation. Kotlyar has served on a number of AGMA technical committees, and he has authored numerous articles on gearing.

My first mentor was Claude Lutz. He dazzled me switching languages from English to German to French and back to English with such an ease that it gave me hope that perhaps one day I would also be able to acquire a better command of English. Despite the fact that my ability to communicate in English was extremely limited, Claude Lutz hired me as a tool designer in January 1980 after my young family and I were lucky to escape the “socialist paradise” of the Soviet Union. That was the beginning of my 13-year career with the American Pfauter. Claude was also a gear guru and a ski enthusiast. Once Claude asked me to organize a collection of some gear standards. That fleeting project revealed to me a “hidden” wealth of the gear knowledge. The standards became my invaluable reference resource - concise and with comprehensive math background. For example, I would recommend to every aspiring gear engineer reading the seemingly timeless gear fundamentals standard DIN 3960. Its beauty is in its brevity.

After about a year designing fixture and automation for hobbing machines, Claude entrusted me with applications engineering work - reviewing customer drawings and making gear manufacturing and metrology proposals. Claude initiated my transition into the application engineering by giving me a half-hour course on the gear geometry & involute generation by the hobbing method that completely confused me, but luckily for me he did not get discouraged.

Thanks to David Goodfellow’s leadership, in the first half of 1980s, in addition to Pfauter hobbing machines, the American Pfauter picked up representation of a large variety of gear technologies: Hoefler Gear inspection machines, Hoefler Gear grinding machines, Kapp Hob Sharpening and Hob Checking machines followed by Kapp Form Gear Grinding technologies, Lorenz shaping machines, Sicmat Shaving machines, Saazor cutting tools, and more. The companies we represented exposed us to a plethora of new gearing ideas, inventions, solutions for involute generation challenges, and perspectives into the art of gear making. It felt as a proverbial being a kid in a candy store.

Sometime around 1986, the American Pfauter picked up representation of Maag gear cutting, grinding, inspection machines, and cutting tools. While Maag CNC Gear Measuring Centers were of great quality, they had no software capabilities beyond gear inspection. One time while riding in a car together, I suggested to Dave Goodfellow that we could develop more software for Maag Gear Measuring Centers SP42/65 here in the USA. Soon after, Dave entrusted me with leading the team of five people, including three software engineers from Maag, to develop software for automatic hob inspection, followed by reverse gear engineering, worm inspection, involute and non-involute spline, circular geometry, SPC, and more.

I was not the only beneficiary of David Goodfellow’s leadership. During his tenure as president of the American Pfauter, a lot of people took advantage of the fertile environment for learning, blossomed, and became experts in the field of gear technology whether they stayed later with Gleason or move on to notable carriers elsewhere.

One of the inspiring leadership lessons I learned from David Goodfellow was that empowering employees - giving them an opportunity to learn, entrusting them with challenging goals, and providing a lot of freedom to create - benefits both the company and employees.

Brian Cluff, Dennis Gimpert, and Geoff Ashcroft were the American Pfauter sales managers and first instructors at the American Pfauter gear school. Although each one of them has a unique style and unique character, they have in common a deep knowledge of the gear art as well as entertaining qualities that made the gear school successful. They also became my early mentors. One of the important lessons I learned from them was that customers very much value the gear education opportunity beyond the bare-bone machine operator training. Brian Cluff championed the American Pfauter gear school and became the chief editor of the Gear Process Dynamics book. Geoffrey Ashcroft, together with his partners, went on to found the Gear Consulting Group that with AGMA partnership has been providing the Basic Gear Training to gear manufacturers. Dennis Gimpert went on to found Koepfer America that, in addition to the machine tools, offers regular gear schools to their customers and to the gear manufacturers at large.

It is impossible to talk about the American Pfauter without mentioning the legendary George Rieder who was so passionate about the hobbing machines that he would harshly scold anyone, not even sparing customers, who did not treat the machines with the proper care and respect. So, it was a great honor for me when George invited me to visit his extended family in Germany during one of our Pfauter visits.

My associate, business partner, a good friend, and a mentor, Ed Driscoll, made a great contribution to the gear industry despite the fact that he knew very little about gears. His experience prior Pfauter was developing computer programs for accounting, financial, and data processing applications. Ed showed up on the American Pfauter scene in the early 80s, when Leon Meuch first acquired computers: IBM System 34 followed by IBM System 36. In a short while after the computer acquisition, Ingrid Chickerling and Leon Meuch, our kind accounting and finance leaders let engineers come a little closer to the computer terminal. One day, I asked Ed Driscoll if he could help me turn a hobbing calculation algorithm into a computer program. No problem, responded Ed and shortly after we had our mainframe predecessor to the Hobtime program.

That was the beginning of our collaboration for many years. Ed and I complemented each other and made a great team at Pfauter and beyond when we went on to develop many gearing, hobbing, cutting tools, and metrology applications together. I admired Ed’s relentless drive to minimize his code, improve its structure and organization. Ed, on the other hand, fully relied on my math models and gear technology algorithms. Ed Driscoll mentored and inspired me as the most resourceful, creative, humorous, and a delight to work with computer genius.

These are just a few short evocations from the early years of my career. But, once again I must acknowledged that there were many more people who inspired and influenced me whether they were brilliant young (some were younger than my children) engineers at Navistar, customers, suppliers, uniquely knowledgeable and generous engineers who volunteer their time for developing AGMA standards, or Italian, German, and Swiss engineers I had an honor to meet.

After forty years working in the gear industry, I still get excited when I learn something new, or meet people who are passionate about their work, and feel fortunate to be connected with this great worldwide gear business and academic community.

Yefim Kotlyar is the Application Engineering Manager at Machine Tool Builders (MTB), responsible for the development of new gear manufacturing and gear metrology technologies. His broad experience in the art of gearing includes the development of various gear cutting technologies, analytical inspection and evaluation technologies for gears and hobs, as well as gear system design and validation. Kotlyar has served on a number of AGMA technical committees, and he has authored numerous articles on gearing.