Items Tagged with 'Star SU'

ARTICLES

Three Days in Motown—Every Gear Is Here

Resources to help you get the most out of your Motion + Power Technology Expo experience

Read More

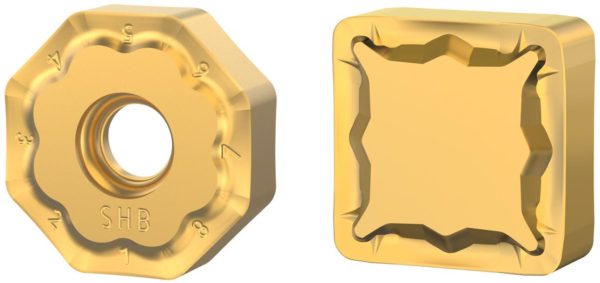

Recent Cutting Tools from Kennametal, Star SU, and Seco Offer Improved Tool Life and Precision

Reliable cutting tools are essential to production-process efficiency

Read More