Reverse Engineering of Pure Involute Cylindrical Gears Using Conventional Measurement Tools

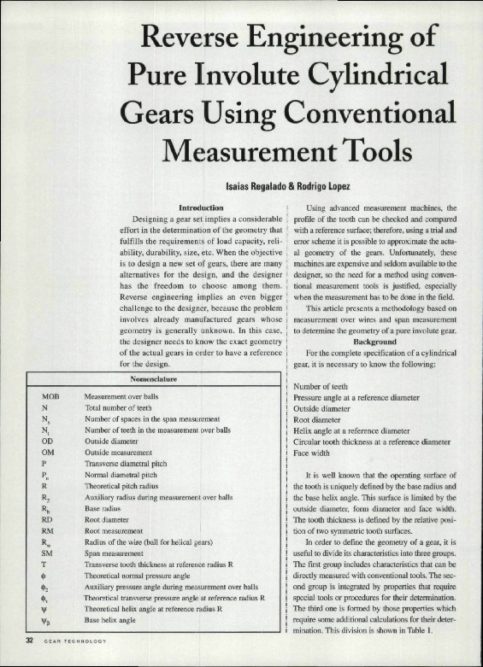

Designing a gear set implies a considerable effort in the determination of the geometry that fulfills the requirements of load capacity, reliability, durability, size, etc. When the objective is to design a new set of gears, there are many alternatives for the design, and the designer has the freedom to choose among them. Reverse engineering implies an even bigger challenge to the designer, because the problem involves already manufactured gears whose geometry is generally unknown. In this case, the designer needs to know the exact geometry of the actual gears in order to have a reference for the design.

Technical