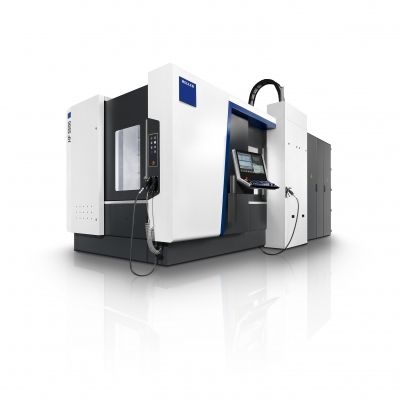

Heller HF Series 5-axis Machining Center Designed for Machining Complex Prismatic Parts

Heller Machine Tools introduces its versatile HF Series 5-axis horizontal machining centers to North America for machining complex prismatic parts from lighter, smaller workpieces to heavier workpieces up to 800 kg table load. In the series of two machines, the fifth axis is provided by the workpiece on a swiveling trunnion with rotary table or a pallet changer for higher volume production. Users can specify from a range of four spindle packages based on the material they are to process. Spindle speeds up to 18,000 rpm and torque up to 354 Nm are available.

According to Heller, the main target groups of the HF series are the general machine industry and automotive suppliers. The two new machine models are Heller's entry into a popular size range for these industries. The HF 5500 offers a work area of 900x950x900mm (X/Y/Z), and the smaller HF 3500 has a work envelope of 710/750/710mm (X/Y/Z).

With three linear axes in X, Y and Z and two rotary axes in A and B integrated into a rotary table on a trunnion, the HF machines are designed for 5-sided machining and simultaneous 5-axis machining. The HF machines may alternatively be equipped with a lift-and-rotate pallet changer for series 5-sided production. Standardized pallet automation solutions may be supplied by Fastems or Schuler.

Contrary to conventional 5-axis machining centers, Heller's concept is not only based on single-part clamping but provides the possibility of multiple clamping or the clamping of very large components (transmission cases using ‘window-type' fixtures).

The NC toolchanger is equipped with two NC axes for short idle times and consistent operation. The chain-type tool magazines capacities are: HSK63: 54, 80 and 160 or HSK100: 50, 100 and150.

As standard, Heller offers the SC63 SpeedCutting unit (18,000rpm, 100Nm) equipped with an HSK-A 63 spindle taper. Optionally available is the PC63 PowerCutting unit (12,000rpm, 201Nm), also equipped with an HSK-A 63 spindle taper, as well as the SC100 SpeedCutting unit (12,000rpm, 201Nm) and the PC100 PowerCutting unit (10,000rpm, 354Nm), both equipped with an HSK-A 100 spindle taper. The HF machines provide a rugged 8000 (HF3500) and 10,000Nm (HF5500) of feed force for handling even the most difficult materials without interruption or strain.