Sharper Eyes on Precision Gears

How multisensor metrology is transforming spur gear inspection with integrated vision and tactile probing

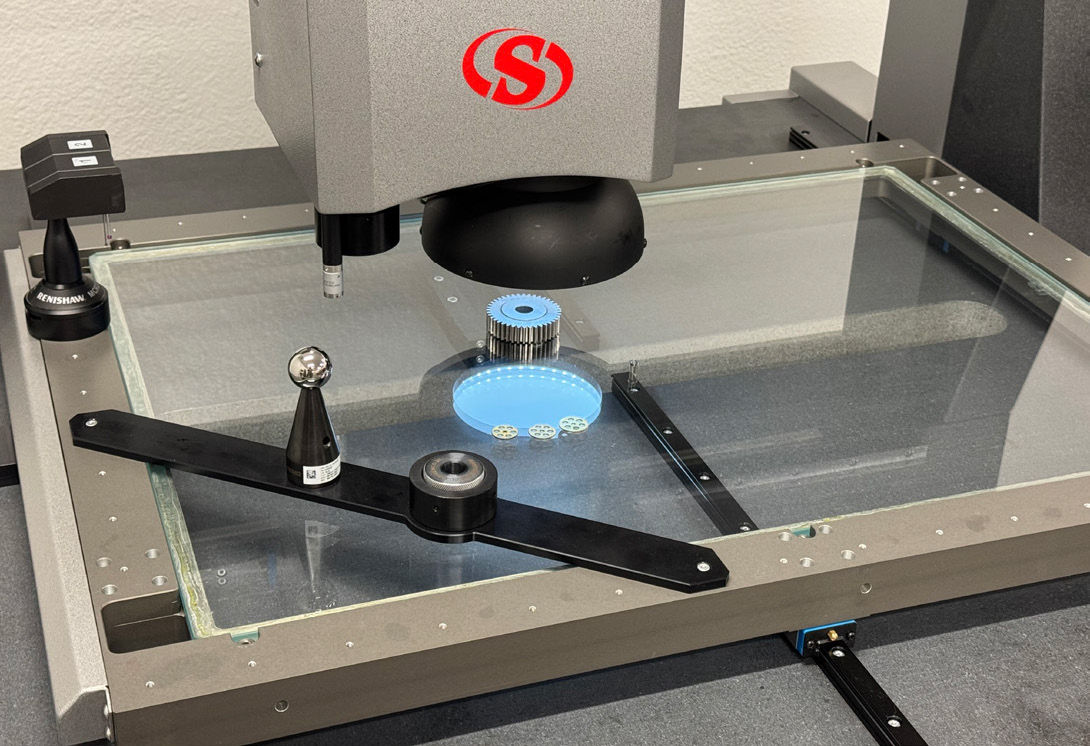

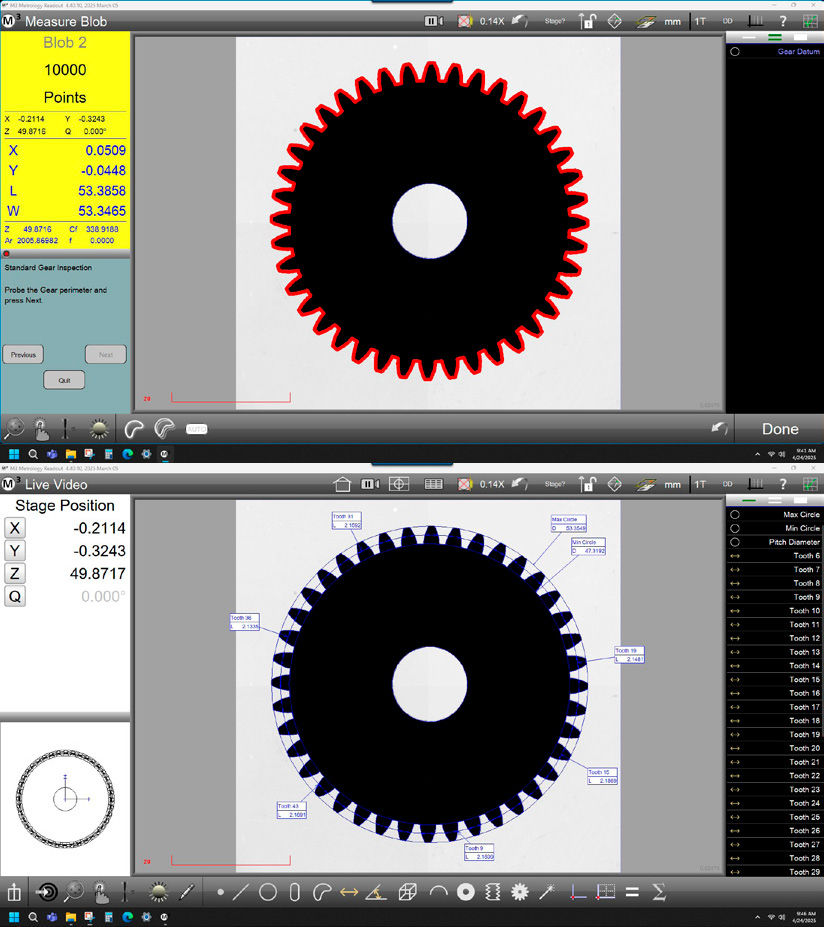

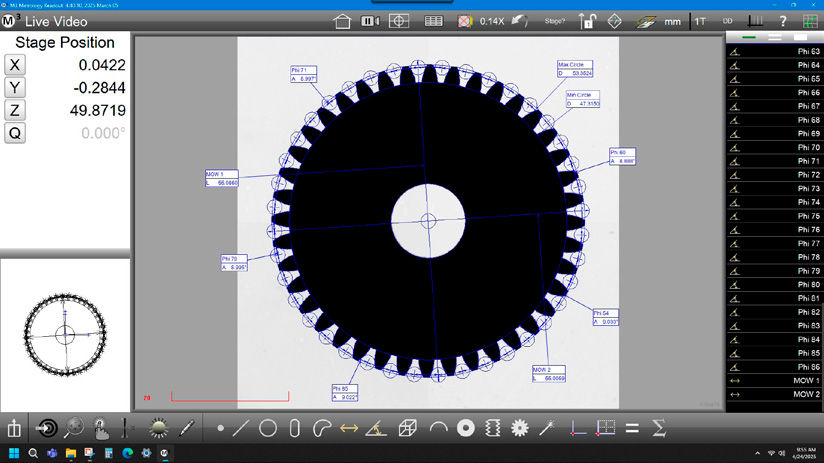

Starrett multisensor metrology system inspecting a spur gear using integrated vision and tactile capabilities. The M3 Gear Module software enables fast, accurate, and repeatable inspection. (Courtesy of Starrett Metrology Systems Division.)

In the world of precision manufacturing, the performance and longevity of many mechanical systems are determined by the quality of their gear components. Accurate gear inspection is vital to ensure that these components meet stringent design specifications and functional performance requirements. However, traditional tactile-based inspection methods can be time-consuming, labor-intensive, and prone to variability, especially as production volumes and complexity increase.

Recognizing the need for a faster, more reliable approach has prompted a new gear inspection solution that combines advanced vision-based measurement with tactile touch-probe capabilities. Central to this is the integration of the M3 Gear Module, developed by MetLogix, along with multisensor metrology systems from inspection equipment manufacturers such as Starrett. The combination offers gear manufacturers and users an efficient, accurate, and repeatable solution for inspecting spur gears that streamlines inspection workflows while ensuring compliance with industry standards.

Using automated edge detection in combination with pre-programmed macros, this solution substantially increases the efficiency with which spur gears are measured via parameters such as maximum/minimum gear diameter, gear tooth width, master gage circle diameter, measurement over simulated/theoretical wires (MOW), and phi angles. In addition to these specific gear measurements, the system can be used to check tooth profiles as well as features that can only be gathered with a tactile probe, such as flatness and planar parallelism. This article explores how the integrated approach enhances both production throughput and quality assurance, providing significant value to manufacturers across a range of industries.

Traditional Impediments

Conventional gear inspection methods have traditionally relied on measurements using hand tools, tactile probing systems, and custom mechanical measurement devices to verify gear geometry. While effective, these methods present several challenges, particularly as demands for higher production speeds and tighter tolerances continue to grow in manufacturing.

Hand tool and tactile-only inspection processes are inherently time-consuming, requiring physical contact with each gear tooth or surface. As a result, the measurement cycle can become lengthy. In addition, the quality of the measurement often depends heavily on operator skill and consistency, introducing potential sources of variability into the inspection process.