Tips for Optimizing Your Cylindrical Grinding Processes

Unlocking next-level precision and efficiency on the shop floor

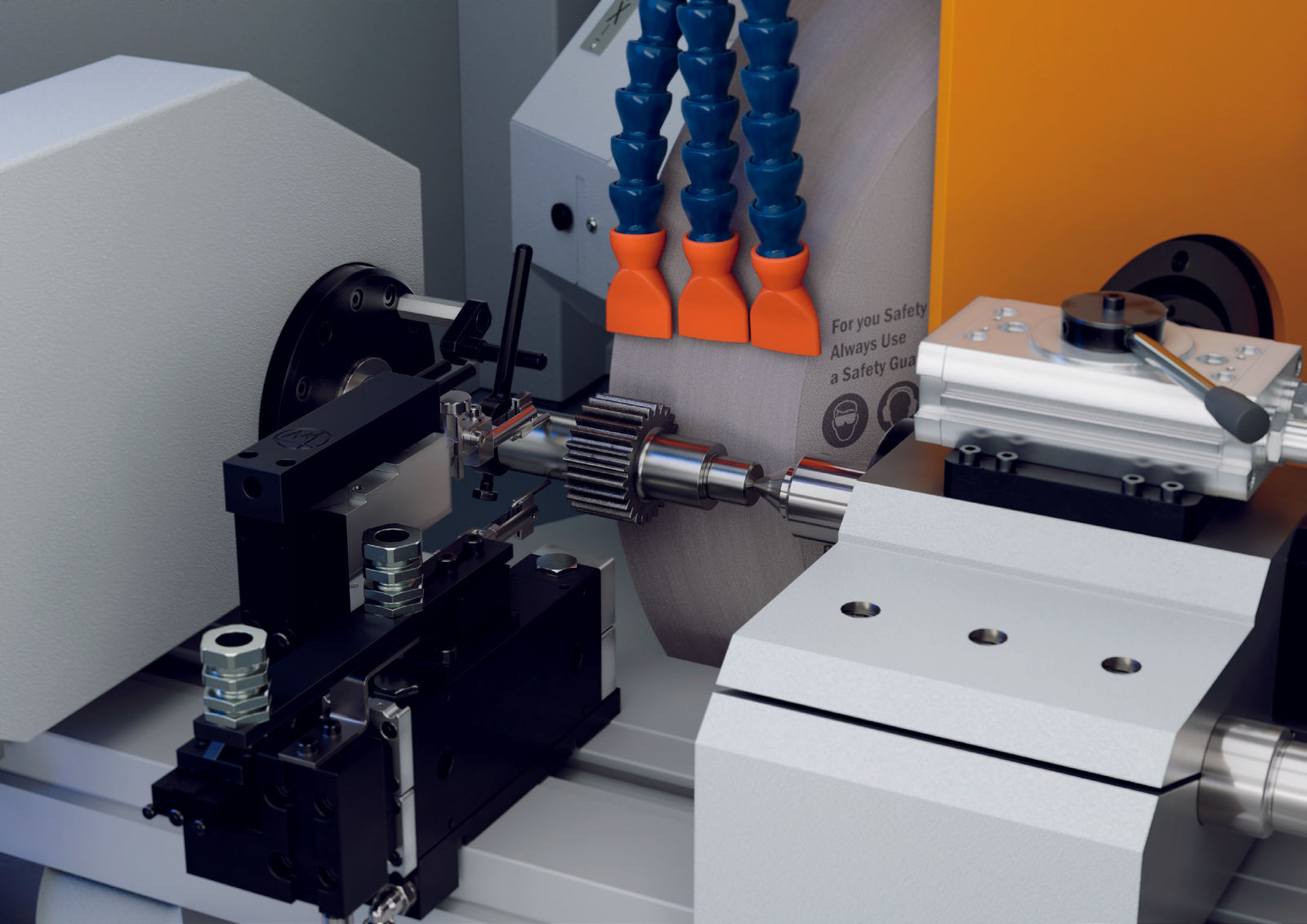

Cylindrical grinding is an essential machining process in precision manufacturing, ensuring that components meet stringent tolerances with superior surface finishes. Optimizing this process involves a strategic approach to wheel selection, process automation, in-process measurement and machine maintenance. This article explores key technical factors that influence the efficiency and accuracy of cylindrical grinding operations.

Grinding Wheel Selection and Optimization

Selecting the appropriate grinding wheel is a fundamental aspect of achieving optimal performance in cylindrical grinding. There are several parameters to consider, and at times, the guiding principles can seem contradictory. A good practice is to consult a trusted expert from an abrasives supplier when the answers seem to point in every direction. Below is some general information on where to start.

- Material Compatibility: The grinding wheel composition should be matched to the workpiece material. Start with the type of material, ferrous or non-ferrous, and then determine the hardness of the material. Aluminum oxide wheels are generally suited for steel or ferrous materials, while silicon carbide is preferred for non-ferrous metals and ceramics. Another grinding wheel category is superabrasives. These can generally be used on any part-material composition and are considered when other types of wheels are not performing well. As in all machining operations, tooling costs are calculated into the overall price-per-part and profitability.

- Abrasive Grit and Bonding: The choice of abrasive grit size impacts surface finish and material removal rates. Coarser grits facilitate aggressive stock removal, whereas finer grits enhance surface quality. The bonding material, or grade of the wheel, must also be selected based on the required wheel durability and heat resistance. Grindability describes how easy or difficult a material is to grind. When dealing with a material with a high-grindability, try starting with a course, durable grit and harder grade. For low-grindability applications, smaller grits with softer grades are a good starting point.

- Operating Parameters: The speed of the grinding wheel and workpiece feed rate must be precisely controlled to optimize cutting forces, such as grinding pressure, prevent thermal damage and minimize tool wear. Part tolerance, finish requirements and part geometry or form will also likely factor into wheel selection. Finding the correct combination of composition, grit size, toughness and grade hardness for the part application will strike an optimal balance between cutting cycle times, machine performance and part results.

Integrating Manual and CNC Techniques

While CNC grinding provides high precision and repeatability, manual techniques remain valuable for specific applications. The selection of grinding methodology should be based on production requirements:

- CNC Grinding for High-Volume, Complex Geometries: Automated CNC systems ensure consistent tolerance and efficiency in many production environments. One area gaining traction at all levels of production grinding is loading/unloading automation. The ability to consistently load parts the same way every time eliminates variables and potentially frees talented personnel to focus on other areas of the production process where they are needed. Although highly engineered custom automation can benefit process optimization and profitability, finding the right supplier while maintaining your project budget can be challenging. Today, machine tool OEMs and distributors offer flexible off-the-shelf part-automation, which can help enhance the process without breaking your budget.

- Manual Grinding for Specialized Applications: Certain low-volume or highly customized components benefit from the skill and adaptability of manual operators. An example where manual grinders are frequently used are in tool-room environments. Manufacturing facilities often require in-house support for rework, part repairs and tooling, which, although limited in quantity, require similar stringent tolerances and quality as the production processes they support.

- Hybrid Approach: In some cases, a combination of CNC and manual grinding techniques can achieve both efficiency and fine-tuned precision.

In-Process Measurement and Quality Control

To maintain consistency and precision in cylindrical grinding, real-time measurement systems should be integrated into the workflow:

- Probing and Sensing Technologies: Advanced optical and tactile probes enable in-situ measurement, reducing the likelihood of dimensional errors. In-process measuring systems contact the part during the grinding. Once the desired diameter is reached, the program disengages the wheel and the process continues.

- Force Monitoring Systems: Continuous monitoring of grinding forces helps in detecting anomalies such as tool wear or excessive heat generation. Production parts often arrive to the grinding process with too much or too little grinding stock. The grinder’s built-in ability to monitor these differences, called “GAP and Collision Control,” improves cycle times and avoids damage to equipment and scrapped workpieces.

- Statistical Process Control (SPC): Implementing SPC methodologies allows for real-time data collection and analysis, facilitating proactive process optimization.

Machine Maintenance Strategies for Performance Optimization

Proper maintenance is critical to sustaining optimal machine performance and extending equipment lifespan. Planning the maintenance for your grinder, conventionally called preventative maintenance, allows facilities to schedule the downtime of equipment and helps to avoid unexpected equipment failures during important production operations. The maintenance guidelines provided by equipment manufacturers should be followed carefully and include some of the following:

- Routine Cleaning and Lubrication: Regular removal of debris and adequate lubrication of moving components prevent premature machine wear and mechanical inefficiencies. Whether your equipment utilizes a manual or automatic lubrication system, ensure the oils or grease are being applied to their intended components, even if they are in hard-to-see locations.

- Grinding Wheel Dressing and Balancing: Periodic wheel dressing maintains abrasive sharpness, while balancing ensures vibration-free operation and improved accuracy. A properly dressed and balanced wheel protects the machine’s spindle bearings.

- Coolant System Management: The effective use of coolant controls heat buildup, enhances surface finish and reduces wheel degradation. Whether the application calls for an oil or water-soluble coolant, proper filtration can help optimize the machining process and keep pumps and hoses clean and free from grinding swarf.

Maximizing efficiency in cylindrical grinding requires a combination of strategic wheel selection, process automation, real-time quality monitoring and diligent maintenance. By implementing these technical best practices, manufacturers can achieve superior precision, reduce downtime and enhance overall productivity in their grinding operations.