American Precision Gear Installs Gear Hobbing Machine from Helios Gear Products

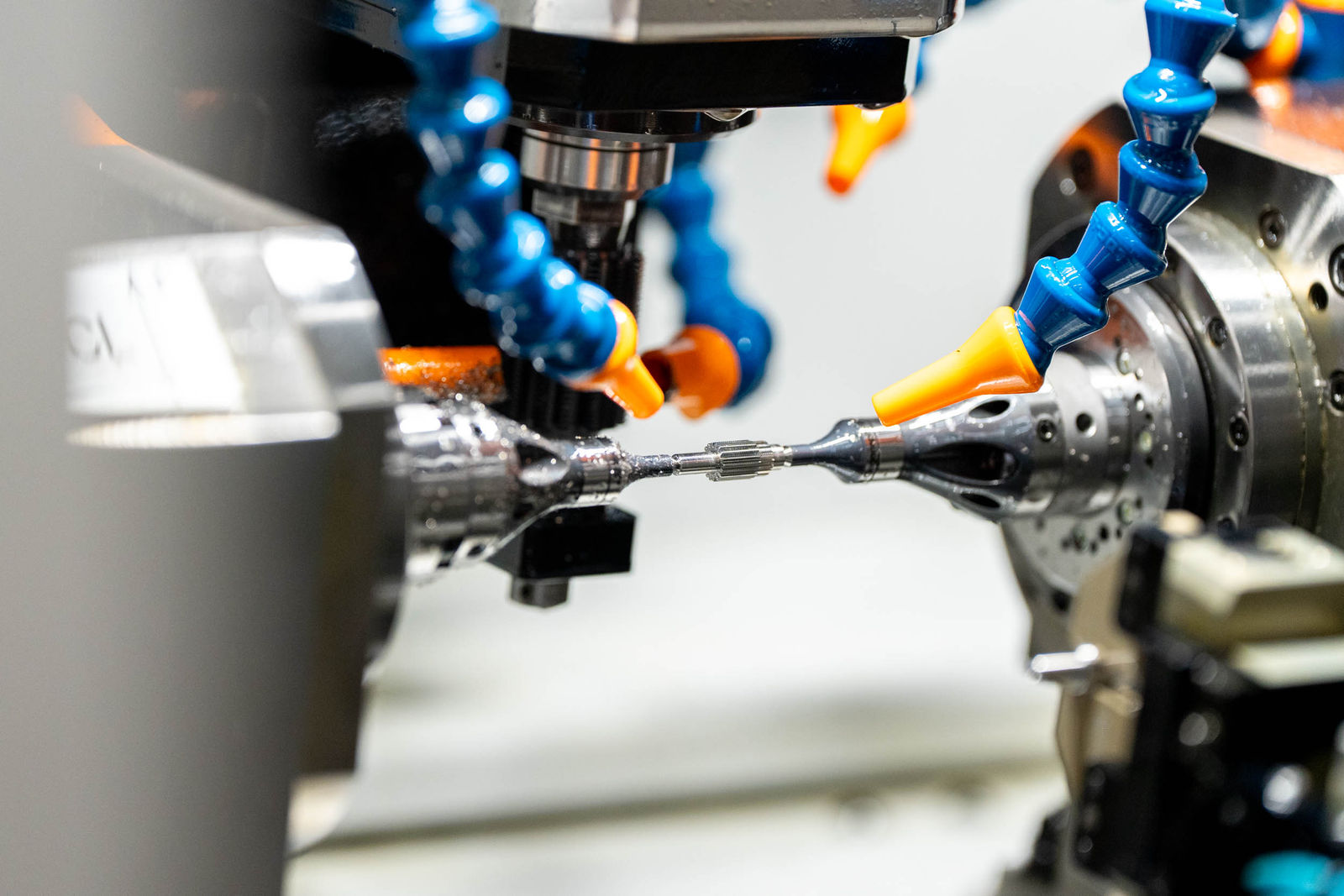

American Precision Gear (APG) has strengthened its manufacturing capabilities with the installation of the MZ 1000 D-Drive gear hobbing machine from Helios Gear Products. This investment not only improves throughput, but also elevates quality and precision machining capabilities, reinforcing APG’s reputation as an industry leader in precision gear manufacturing.

Commitment to Quality and Innovation

At APG, quality is non-negotiable. “We spend more time inspecting parts than we do operating machines,” explains Jarrod McClendon. “Every component is checked multiple times before leaving our facility. Customers rely on us for quality, and we take that responsibility very seriously.”

The MZ 1000 D-Drive has been a game-changer, allowing APG to maintain its meticulous standards while significantly improving cycle times, operational efficiency, and overall productivity. Previously, a single gear could take 4-5 minutes to process manually. Now, with advanced automation and streamlined workholding, the same job can be completed in just seconds, often running lights out through the night.

Automation and Productivity Gains

The MZ 1000 D-Drive has significantly improved APG’s ability to handle complex parts with extreme tolerances. “Some of our parts are so demanding — AGMA 12 and above, with near-zero tolerance on test radius — that they were incredibly challenging to produce at scale,” explains Jarrod. “The MZ 1000 D-Drive completely transformed that. It holds tolerances down to a micron with remarkable consistency, making even our toughest jobs not only possible, but now the easiest jobs in the building.”

Prior to this upgrade, APG relied on manual setups and extensive in-process inspections, leading to workflow bottlenecks. With the MZ 1000’s synchronized headstocks and universal rail system, APG has streamlined operations, reduced setup times, and improved tool life by 200-300 percent. “What used to take weeks now takes days, and what took days now takes hours,” says Tyler, a lead gear machinist at APG.

A Collaborative Approach to Success

APG credits its success to a culture of community and continuous improvement. “Our collaborative leadership and focus on quality in the machine shop sets the tone for the entire company,” says Jarrod. “The machinists collaborate, cross-train, and focus on the little things that ensure quality and throughput. Our gear shop has followed their lead, and our partnership with Helios has only strengthened that.”

Deburring, one of the most challenging aspects of fine-pitch gear manufacturing, has also contributed to their dedication to quality. “Our deburr team is detail-oriented and uncompromising,” adds Jarrod. “Many of them are family or close friends, so they naturally help each other find solutions.” With the MZ 1000 reducing required deburring needs by 80-90%, the deburring team can process more parts with the same meticulous attention to detail.