Verisurf Software CMM Surface Finish Measurement

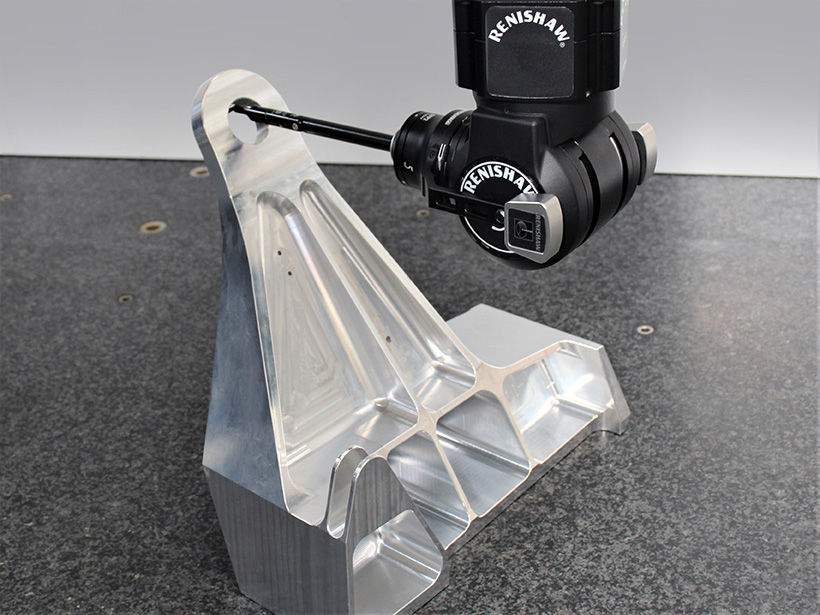

Verisurf Software, Inc. announces a surface finish measurement probe and reporting solution for CNC CMMs equipped with Renishaw REVO SFP2 (Surface Finish Probe).

The surface finish measurement feature is included in the soon-to-be-released Verisurf 2024. Using direct output from the Renishaw REVO SFP2 probe, Verisurf CMM programming can include defined surface finish/roughness evaluation from 6.3 μm to 0.05 μm (250 μin to 2 μin) Ra with results added to automated quality reporting. This is made possible by Verisurf support for Renishaw REVO multi-sensor 5-axis measurement system. Surface finish measurement is fully integrated with the standard Verisurf CMM inspection program and includes automatic changing of probes, based on the inspection plan, which eliminates CMM downtime, and maximizes inspection throughput.

The REVO SFP2 works on a variety of surfaces including bores as small as 5mm (.196”) using a 2, 5, or 10-micron radius diamond stylus tip, and can output Ra, RMS, and raw data for further analysis and reporting. When combined with Verisurf the solution provides detailed and accurate data that can be verified against a nominal 3D CAD model, enabling operators to make informed decisions regarding component quality and acceptability.

Verisurf operates Renishaw-equipped CNC CMMs through the Verisurf Device Interface (VDI), which supports two-way communications with virtually all sensor types and brands. The VDI sends programmed instructions to operate the CMM and collects measurement data for analysis and processing.

“Our goal is to help customers get the most out of their CMM investment. Being able to evaluate surface finish/roughness as part of an overall inspection plan with automated reporting is huge, and we are excited to be at the forefront of this technology. Depending on the application, many customers can reduce or eliminate the need for dedicated optical and stylus profilometers,” said Nick Merrell, Executive Vice President of Verisurf Software, Inc.

Verisurf is the only measurement, reverse engineering, and inspection software built on a full-featured 3D CAD/CAM platform with intelligent Model-Based Definition (MBD). This ensures data integrity and lets users perform metrology workflows in a seamless CAD environment while maintaining model-based digital continuity. Verisurf software is compatible with all CAD file formats, and the Verisurf Device Interface (VDI) communicates with and operates all programmable and portable CMMs for universal compatibility. The software’s modular design enables users to quickly shift from reverse engineering to inspection to tool building, efficiently capturing and processing measurement data for practical metrology applications, with repeatable process control, across the manufacturing enterprise.