Mechanochemical Surface Finishing for High-Speed Gears for EV Transmissions

Meeting the noise and efficiency demands of the electric drivetrain era

Powertrain electrification has been a growing trend in the automotive industry. Electric motors used in battery electric vehicles (BEVs) operate at high speeds ranging from 3,000 to 16,000 rpm, with high-performance motors reaching over 20,000 rpm. For instance, Tesla’s carbon-sleeved motor used in Tesla Model S Plaid may reach 24,000 rpm at the top speed of 330 km/h. There are experimental designs of interior permanent magnet synchronous motors (IPMSM) reaching 100,000 rpm. The combined inverter/motor efficiency of a typical BEV equipped with a single-speed reduction gearbox reaches a maximum close to the maximum motor speed. Small high-revving motors achieve higher power density and are also lighter and cheaper to manufacture. However, a single-speed gearbox cannot ensure optimum efficiency and driving comfort at different speeds and loads. Hence, quite a few multi-speed gearboxes have hit the market over recent years. Even though the use of a multi-speed gearbox tends to increase the engineering complexity and manufacturing cost of an EV, it is well justified for premium passenger cars, off-road vehicles, and commercial vehicles due to improvements in the driving range, dynamic performance, and gradability (Ref. 1).

Higher speeds of electric motors bring new challenges with lubrication, heat management, and noise. Gear meshing is the primary source of an intrusive whining noise that irritates most drivers. This noise is usually linked to a transmission error and geometric imperfections of the gears. For example, profile angle deviation (fHa) and tooth trace angle deviation (fHb) have been shown to have a significant impact on the noise level through the gearing process (Ref. 2).

Gear microgeometry also has a significant impact on the contact pressure and temperature distribution for meshed gear flanks. Certain modifications, such as crown, taper, and tip relief, have particularly large effects on gear tribology (Ref. 3). Suboptimal microgeometry is associated with an increased risk of scuffing, which is particularly common in transmission gears operating under long-duty cycle hours (Ref. 4).

Gear design usually includes specific optimizations to address issues such as efficiency, noise, and service life. However, it is not always possible to improve all characteristics simultaneously. Perfect gears exist only in theory. In practice, gear manufacturers must always strike a balance between quality and price, which varies a lot from application to application. Gears used in EV transmissions have significant differences in design and, in general, tighter tolerances compared to gears used in traditional stepped and dual-clutch transmissions for ICE-powered cars.

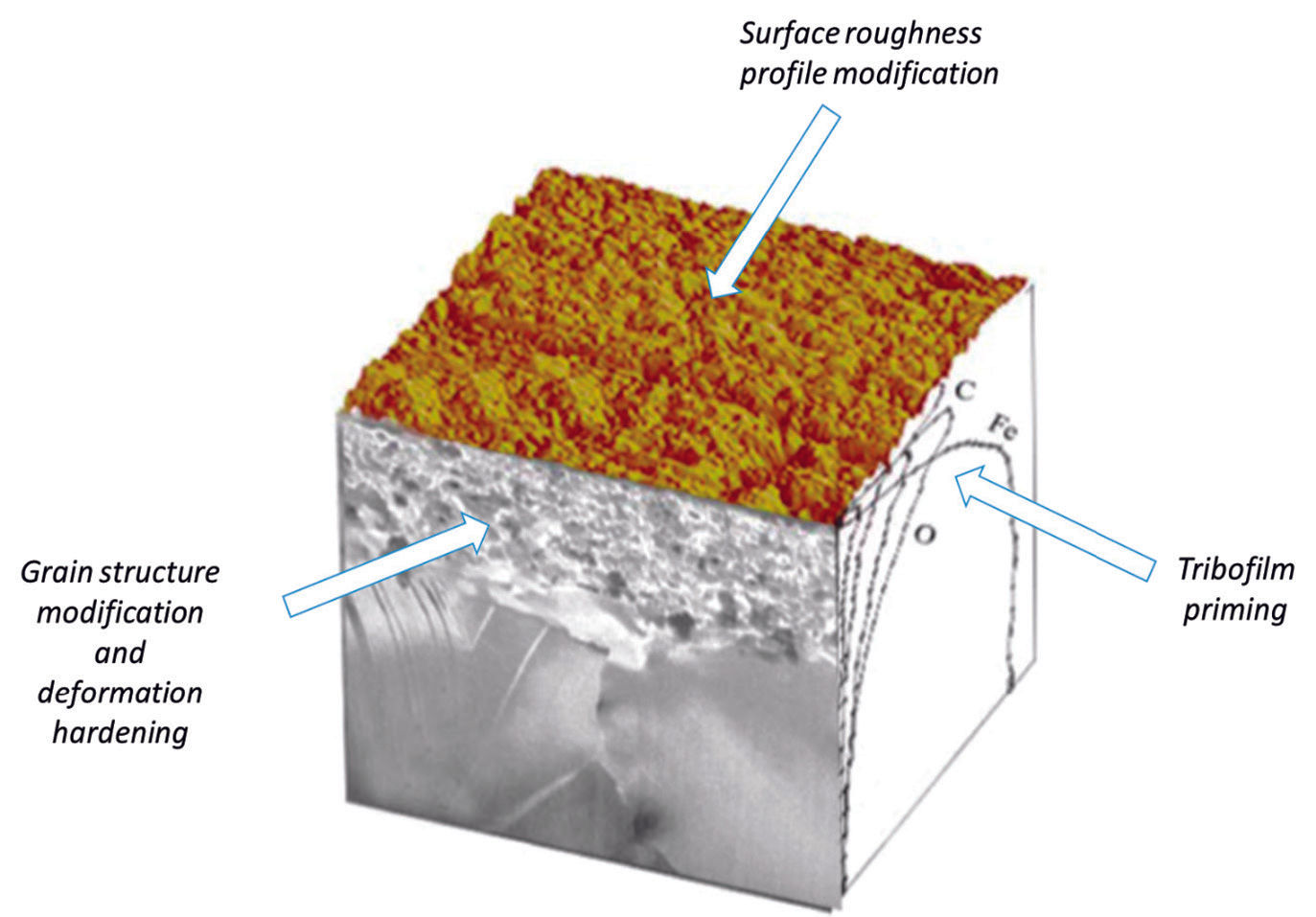

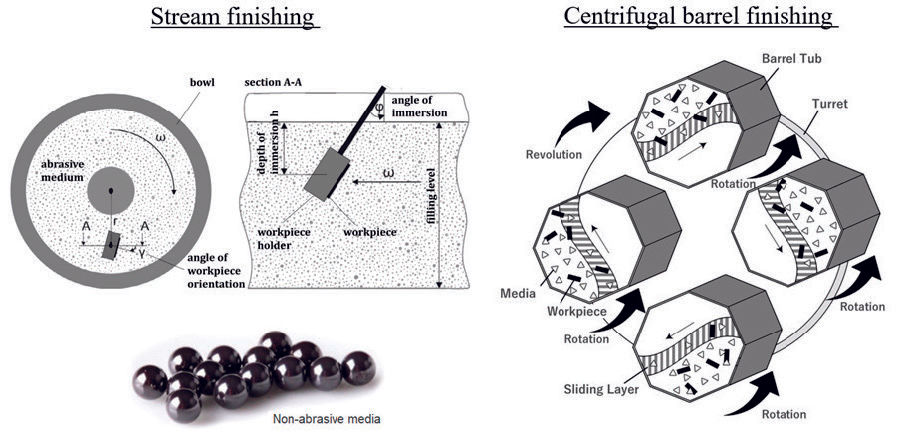

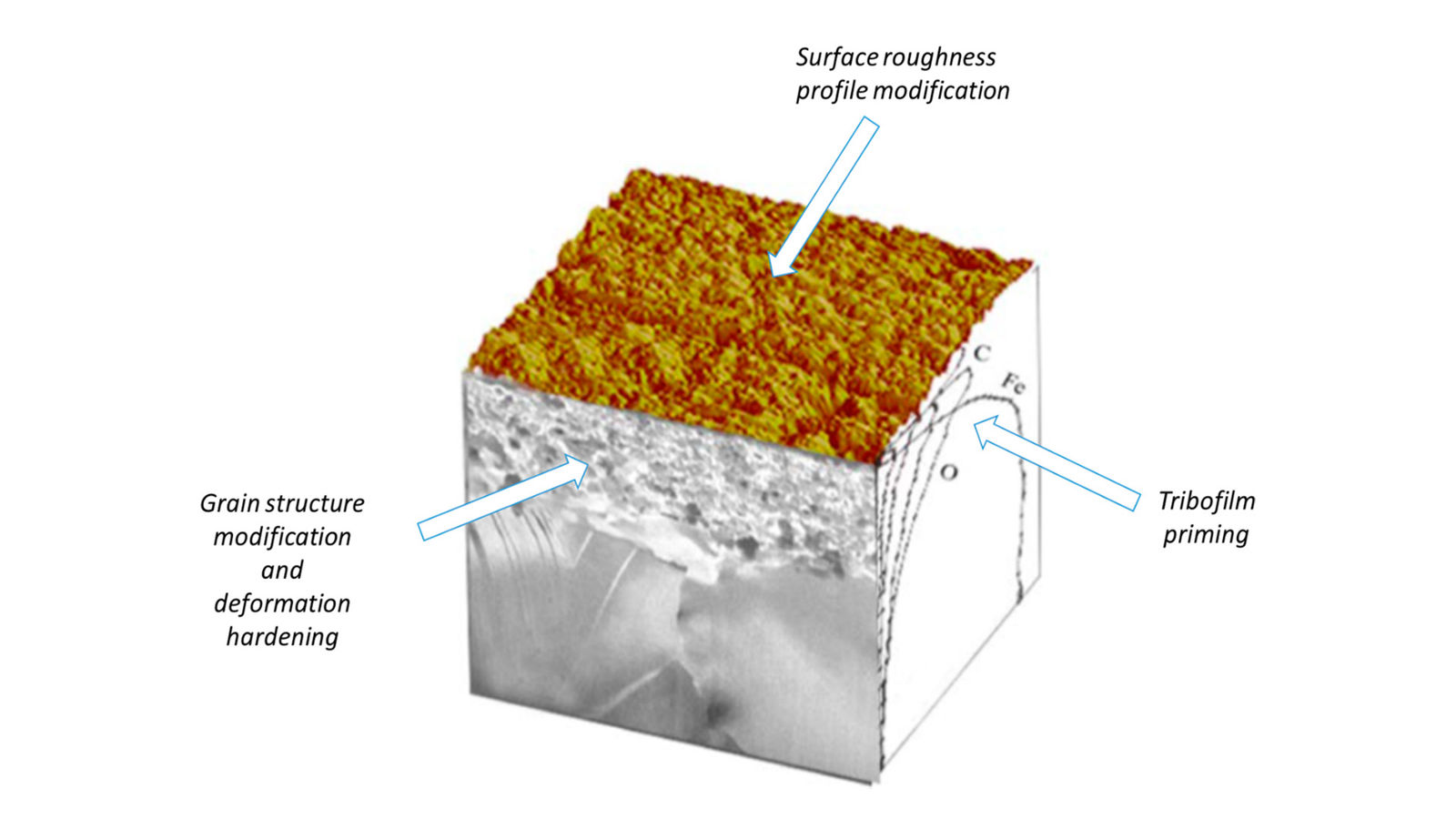

The adequate accuracy for gears used in electric vehicles is around ISO 1328 Grade 6, but high-speed gears rated for speeds over 20,000 rpm may have even higher quality requirements. The contact mechanics in the gear-tooth contact are sensitive to shape deviations at different wavelengths: form, waviness, roughness and microstructure. To optimize the load capacity and the NVH behavior, lead modifications are introduced (Ref. 5). Unfortunately, many traditional gear-cutting techniques, such as generating grinding, profile grinding, gear hobbing, shaving and honing, are plagued by twist errors. To address this problem, special process control or tool geometry adjustment methods have been developed to minimize twist errors in the manufacturing of gears (Ref. 6). To improve transmission efficiency, higher surface quality on tooth flanks is required. This leads to a wider use of advanced surface finishing technologies such as fine grinding or polish grinding (Ref. 7). For instance, with conventional generating grinding, it is challenging to go below Ra 0.5 µm, but when using a combined polish-grinding process, one can reach Ra around 0.1 µm. Mass-finishing processes such as accelerated surface finishing (ASF) and isotropic superfinishing (ISF) allow even smoother surfaces, with Ra down to 0.01 µm. Recently developed mechanochemical surface finishing methods, such as Triboconditioning CG process developed by Tribonex AB, can be used as the final finishing operation bringing about a triad of effects: (i) surface roughness profile optimization, (ii) compressive stress buildup, and (iii) tribofilm priming, which greatly improves the tribological and NVH behavior of gears (Refs. 8,9). Triboconditioning CG treatment can be carried out using standard mass-finishing equipment, such as vibratory tub finishers, centrifugal barrel finishers, and stream- and drag-finishers (see Figures 1–3). The major difference is the use of special chemically reactive process fluids and media types.