TCI Precision Metals Introduces Automation-Ready Blanks

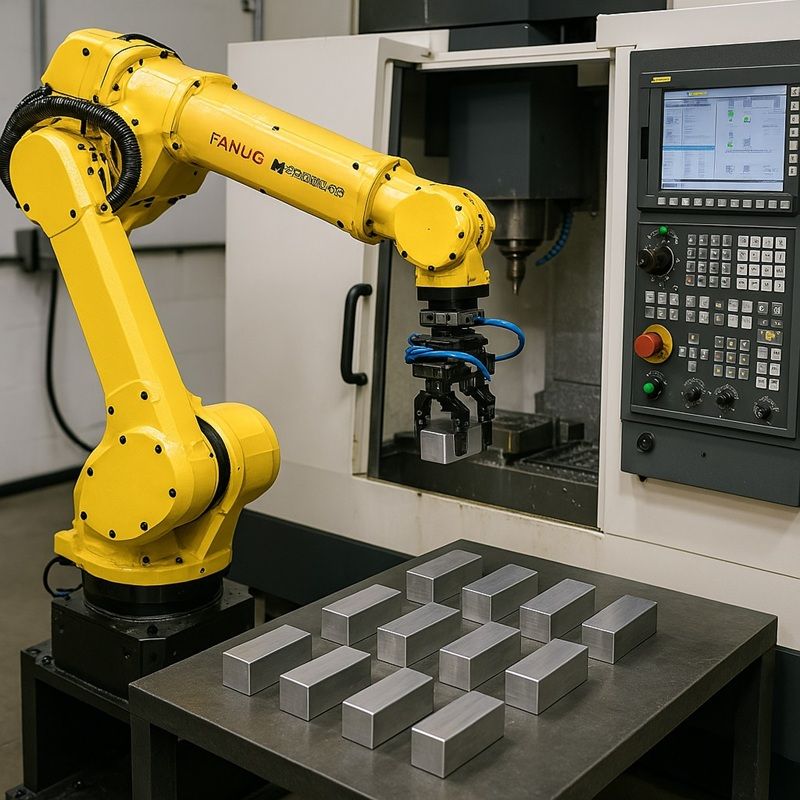

TCI Precision Metals introduces new automation-ready materials designed to help manufacturers increase machining throughput and improve precision and consistency part-to-part. The materials solution combines pre-production planning support, customized materials, and JIT materials logistics.

TCI's materials experts work directly with shop floor management to design the right materials strategy for each automated cell. This includes considerations for material type and pre-production processes such as heat treating, handling, gripping, clamping, and related tooling. Test materials are then produced for validation. Once approved automation-ready blanks are produced and delivered based on JIT production scheduling. Automation-ready blanks arrive certified to specifications and ready to be added directly to automated work cells.

“Successful automation relies on consistency, starting with materials. The more variables you can eliminate, the better the outcome. Materials that are certified Automation-Ready mean you can count on them being close tolerance, flat, square, de-stressed, clean, and ready for repeatable precision processing. On the other hand, inconsistent material properties can contribute to inconsistency, leading to rework, scrap, and bottlenecks,” according to President and CEO of TCI Precision Metals, Ben Belzer.

Automation-ready blanks eliminate the need for in-house sawing, grinding, flattening, squaring operations, and outside processing. Each blank arrives deburred, clean, and individually packaged to avoid damage during shipping. Automation-Ready Blanks are close tolerance and consistent blank-to-blank. Each one is produced to customer specifications and is guaranteed as close as +/- .0005” dimensionally and as close as .0002” flatness, squareness, and parallelism.