A Legacy of Precision, Innovation, and Global Leadership

For over 160 years, the Gleason name has been synonymous with groundbreaking advancements in gear technology.

From its origins as a small machine shop to becoming a global leader in precision engineering, Gleason Corporation has continuously redefined the industry. This journey, marked by pioneering inventions and strategic expansions, has left an indelible mark on sectors ranging from automotive and aerospace to robotics and renewable energy.

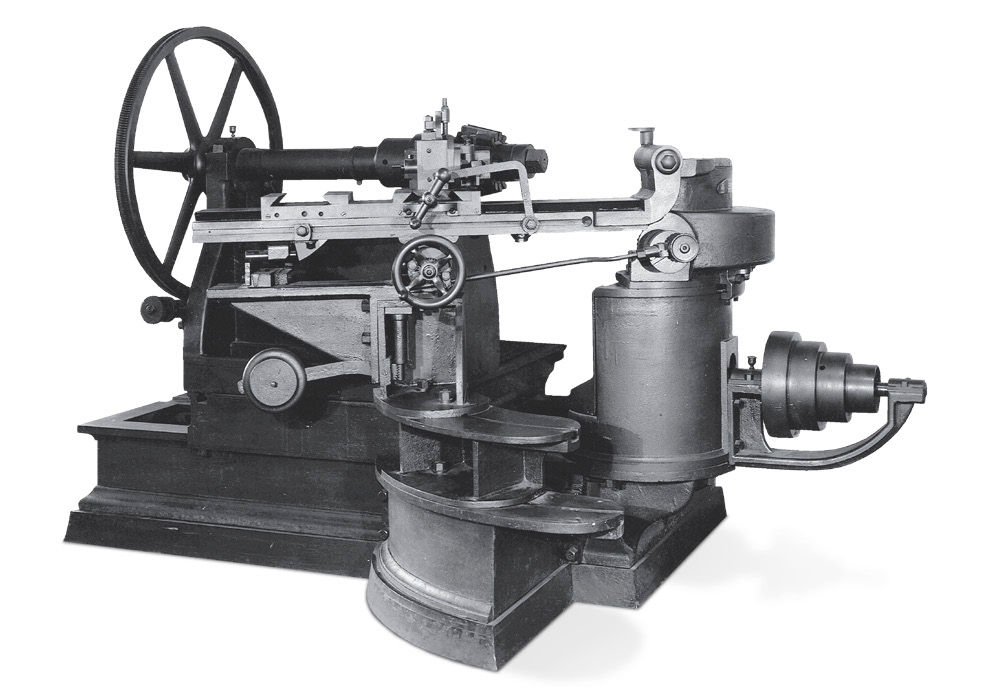

The Gleason story began in 1865 when William Gleason established his first machine shop in the Brown’s Race district of Rochester, NY. His commitment to precision engineering quickly gained recognition, but it was the invention of the first bevel gear planer in 1874 that transformed the industry. This innovation enabled the mass production of gears with unprecedented accuracy, setting the foundation for Gleason’s future dominance. In 1876, the growing demand for precision gears led William to formally establish The Gleason Works—a company built on craftsmanship and a spirit of continuous innovation. What began as a small workshop soon evolved into a full-scale manufacturing enterprise supplying gear-cutting machines worldwide. As demand for high-quality gears grew, Gleason officially relocated in 1905 to University Avenue, Rochester, NY, which became one of the most advanced industrial sites in the region. The new headquarters allowed for increased production, research laboratories, and training facilities. In 1916, Gleason became a founding member of the American Gear Manufacturers Association (AGMA), helping to establish unified quality standards for gears—a commitment to precision that remains central to the company’s philosophy today.

Engineering Breakthroughs and Gear Education

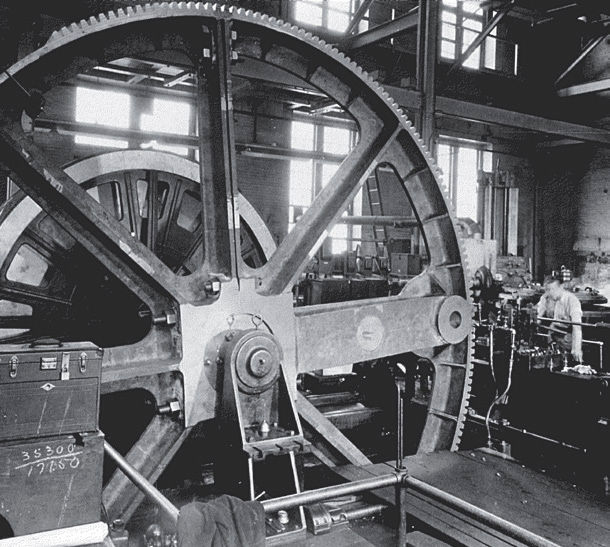

Throughout its history, Gleason has been at the center of major industrial milestones. As early as the 1880s, its bevel gear technology powered railway expansion, ships, and mining operations during the height of the Second Industrial Revolution. By the early 20th century, Gleason machines were operating on nearly every continent. Gleason’s innovations played a crucial role in numerous engineering landmarks, including the Panama Canal, where its precision gears were integral to the canal’s lock systems. The massive gears, some exceeding 20 feet in diameter, were produced on specialized Gleason planers—a feat of mechanical engineering at that time.

To sustain its rapid growth, Gleason launched its first Gear School in 1919, offering structured training for engineers and machine operators. This institution would later evolve into a global center of excellence for gear technology training, the very foundation of what today makes Gleason the number one in education and training for gear manufacturing worldwide.

The introduction of the Hypoid Gear in the 1920s, designed by Gleason’s Ernest Wildhaber, revolutionized the automotive industry by improving drivetrain efficiency, enhancing vehicle performance, and enabling modern differentials. Gleason’s patented manufacturing process quickly became the global standard, powering the automobile revolution. During the 1930s and 1940s, the company also contributed to the aviation and defense industries, providing the precision required for aircraft and naval systems. Curvic couplings provided a highly precise gear connection, improving alignment and power transmission in industrial turbines and jet engines. These couplings became indispensable in the aerospace industry and were even used in NASA’s Apollo Space Program, helping humanity take its first steps on the moon.