Design Unit Evaluating New Software from SMT

MASTA 4.5.1 MODELS COMPLETE TRANSMISSIONS AND INCLUDES 3-D STRESS ANALYSIS

Smart Manufacturing Technology (SMT) has announced the launch of MASTA 4.5.1. The software, which enables users to conduct fully integrated system analysis of mechanical

transmissions, is undergoing intensive evaluation by the Design Unit at Newcastle University, U.K.

The Design Unit is widely recognized as an authority in gear design and manufacturing technology. The Design Unit has produced the DU-Gates program, which includes a 3-D analysis of a gear pair, enabling accurate prediction of root stresses and transmission error.

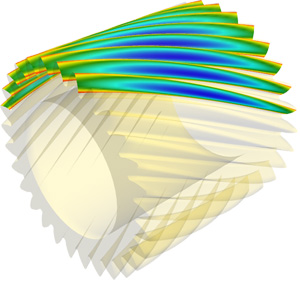

“The new MASTA software provides a 3-D gear stress analysis module whilst taking into account system deformations, and should therefore bring us closer to predicting the operating conditions on gears,” says Dr. Brian Shaw, director of Newcastle University Design Unit. “The MASTA software appears very powerful, and we are enjoying working with SMT to validate the gear stressing routines.”

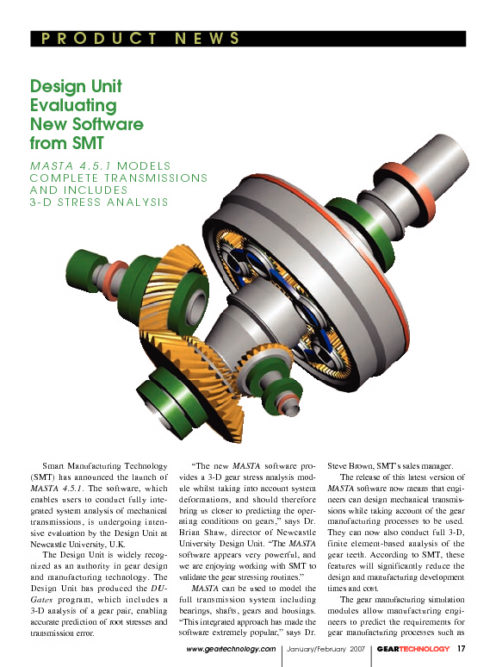

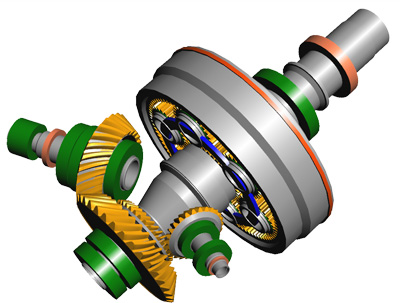

MASTA can be used to model the full transmission system including bearings, shafts, gears and housings. “This integrated approach has made the software extremely popular,” says Dr. Steve Brown, SMT’s sales manager.

The release of this latest version of MASTA software now means that engineers can design mechanical transmissions while taking account of the gear manufacturing processes to be used. They can now also conduct full 3-D, finite element-based analysis of the gear teeth. According to SMT, these features will significantly reduce the design and manufacturing development times and cost.

The gear manufacturing simulation modules allow manufacturing engineers to predict the requirements for gear manufacturing processes such as hobbing, shaving, shaping and grinding. “Much of the time during gearbox development is spent solving gear manufacturing issues,” says SMT director Dr. Changxiu Zhou. “Our software now allows most of these problems to be solved before metal is cut, saving our customers large amounts of time and money. This technology has been driven by demands from our customers to reduce the process development phase so they can get their products into the marketplace faster and more economically.”

The Design Unit’s evaluation of the MASTA 3-D gear analysis module goes beyond the commonly used gear standards such as ISO 6336 and AGMA 2001 to give a full 3-D stress analysis. “Accurate prediction of root and contact stresses for gears with high helix angles and contacts ratios is becoming evermore necessary,” explains Shaw.

Advanced contact modeling of rolling element bearings ensures that the calculated bearing deformations and contact stresses are accurate. This leads to a more reliable prediction of gear mesh misalignment, which is essential in determining in-service gear contact conditions.

For more information:

Smart Manufacturing Technology Ltd.

14 Regent Street

Nottingham, Nottinghamshire NG1 5BQ

England

Phone: +(44) 115-941-9839

Fax: +(44) 115-950-9278

Email: info@smartmt.com

Internet: www.smartmt.com