Product News

Product News - May 2018 Gear Technology

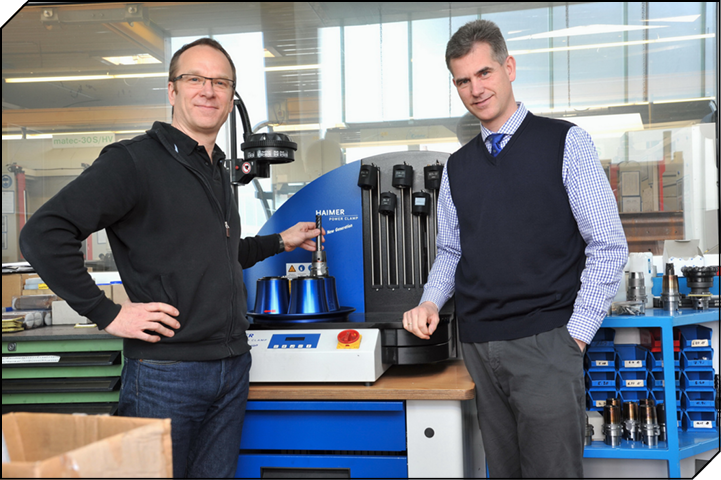

Haimer

Safe-Lock Ensures Safe Cutting Tool Clamping

The Haimer Safe-Lock pull out protection system ensures safe cutting tool clamping. Special drive keys in the tool holder perfectly match the spiral shaped grooves on the cutting tool shank, thus creating frictional clamping forces and a positive locking form-fit. This effectively prevents the cutting tool from pulling out of the tool holder. Furthermore, it increases the productivity through faster permissible speeds and increased tool life.

By now Safe-Lock has become a de-facto standard in the area of tool holding for milling operations. Within the last ten years, since the introduction of the Safe-Lock system, it has been confirmed over and over that this method of clamping the tool is often clearly superior to conventional Milling Chucks and Weldon shanked tool holders. This is proven by a large number of license partners including Walter, Widia, Sandvik Coromant, Seco Tools, Sumitomo, Kennametal, Helical, Emuge Franken, Data Flute, Niagara, OSG and Mapal.

In 2017, Iscar and Ingersoll also decided to offer tools with the Safe-Lock shank. Furthermore, the shrink, collet and hydraulic chuck Safe-Lock tool holder portfolio has become much larger within the last few years. In addition to the Safe-Lock hydraulic chucks from Kennametal, Mapal is already working to introduce its hydraulic chuck offering with Safe-Lock to the market.

Andreas Haimer, managing director of Haimer GmbH said, “We are proud that our Safe-Lock pull out protection system has established itself as the new standard in the heavy duty and rough milling industry and is also becoming more and more important in other areas such as trochoidal milling. We are also very happy about our new license partners, who help expand the Safe-Lock portfolio and also make it available for more end-users.”

Successful in the Aerospace Industry

Safe-Lock has emerged from the requirements of heavy-duty machining, which is a daily challenge in the aerospace and energy producing industries. Innovative materials such as various titanium alloys are not only light, but also very rigid, corrosion resistant and difficult to machine. This doesn´t only affect the machine concepts and processes, but also the cutting tools and tool holders that are being used.

Many workpieces are made from a solid block - during this milling process up to 90% of the material is being removed. In order to optimize the process economically as well as qualitatively and in order to achieve a high metal removal rate, high torques and feed rates with low rpms are chosen. But during this High Performance Cutting operation (HPC), high pulling forces occur. In combination with high cutting forces and aggressive feed rates, a flexing movement of the tool in the tool holder is created which in the end increases the risk of tool pull out. This especially affects all the tool holder designs which provide accurate clamping and a high run-out accuracy, like for example shrink, hydraulic or milling chucks.

As a consequence Safe-Lock is now widespread within the aerospace industry. Alexander Steurer, senior manager NC - Programming Stator Components at MTU Aero Engines in Munich, explains the decision to use the Haimer system:

“Through the introduction of Safe-Lock and the shrinking technology from Haimer, we can guarantee process reliability even with milling challenging high temperature materials. This is a prerequisite to guarantee smooth processing during manufacturing of frames and castings, given our high degree of automation.”

The combination of pull-out protection and highest concentricity of the Safe-Lock™ system leads to low vibration and as a result, a very stable machining process. Due to the increased cutting depths and feeds, the metal removal rate can be increased significantly. And thanks to the improved runout accuracy of Haimer shrink fit chucks, tool life is improved by up to 50%.

The benefits of less than 3 μm runout, that the symmetrical Safe-Lock design provides, coupled with optimum balance and the possibility for easy length presetting were substantial reasons for MTU to switch to the Haimer system instead of continuing to use Whistle Notch or Weldon tooling systems. While these other systems do in fact prevent tool pull out, both are unsymmetrical by design, hence providing insufficient runout and balance accuracy.

Higher Productivity with Safe-Lock

However, Safe-Lock has not only found enthusiastic followers in the aerospace industry. Working at Glätzer, Daniel Rautenbach knows how fiercely competitive and thorough the automotive industry can be. The Managing Director of the CNC-Machining Specialists located in Solingen explains: “Perfect quality and delivery reliability are the basic requirements in order to quote in our industry. Pricing is highly competitive.” Therefore, in his business, the difference between profit and loss comes down to process efficiency. Hence quality without compromise is a must.

Through one of the biggest projects in this area Ingo Schulten, operation manager, became aware of the Haimer Safe-Lock pull out protection system and started using it in the middle of 2013. The specific application was a part for a pneumatically operated truck disk-brake which consisted of spheroidal-graphite cast iron, Type EN-GJS-800-2. In order to mill concave contours the contact between cutting tool and the workpiece isn´t just punctual, but it actually covers between 30 or 40 percent of the tool.

“The extremely high engagement and cutting forces cause the tool to want to pull out from the holder,” said Schulten. The utilized Weldon Chucks ensured that the cutting tool stayed in the holder, but the side lock screw prevented the tool from achieving good runout accuracy. According to Schulten “The tool life was very unstable which even led to tool breakage.”

Benefits of High Speed Cutting

Safe-Lock is also becoming increasingly popular in other industries and during HSC machining with high-helix end mills as well as in trochoidal milling. During trochoidal milling operations, where the cutting speed and axial depth of cut can be increased through software support, the productivity is significantly improved. Thus milling operations are carried out three times faster with deeper depths pf cut, even when it comes to hard and difficult to machine materials.

However this also increases the danger of tool pull out. Even though only a thin chip is usually removed during trochoidal milling operations, often the entire length of the cutting tool edge is used during the process. This results in higher axial forces which force the operator to pay attention to safe cutting tool clamping. A shrink fit chuck with Safe-Lock is the ideal solution since it offers more security than the Weldon system, is easier to install and can be clamped very precisely. The ideal balancing and runout characteristics of the shrinking technology in combination with the clamping safety of the Safe-Lock system permit the possibility of greater productivity achieved through faster permissible speeds and increased tool life all with complete tool security assurance.

For more information:

Haimer USA, LLC

Phone: (630) 833-1500

www.haimer-usa.com

Nagel

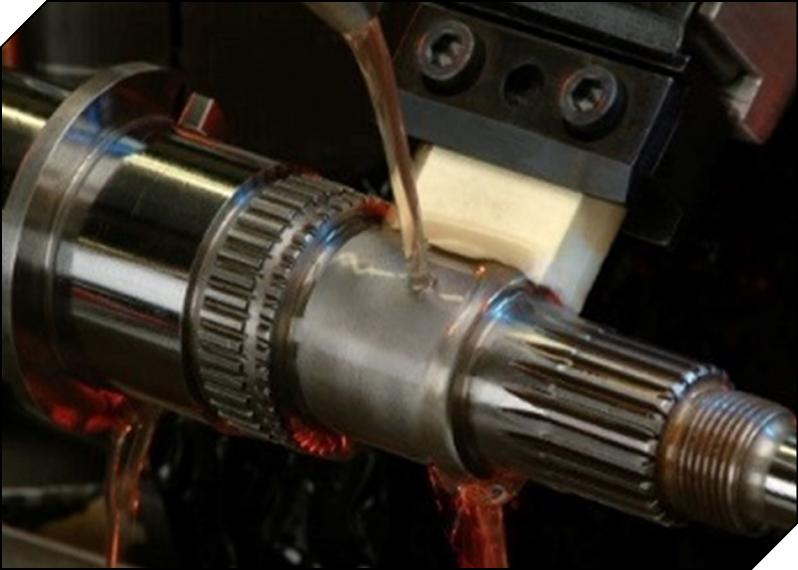

Responds to Growing Trend in Superfinishing

Whether to reduce friction losses or improve hygiene the surface quality of components is always in demand. As a result, superfinishing technologies have grown in significance. Nagel Maschinen- und Werkzeugfabrik GmbH in Nürtingen has responded to this trend by increasing capacities for process development and contract manufacturing in the area of superfinishing.

The growing demand for high-quality surface finishes has far-reaching consequences for many metal processing companies: their process chain becomes longer due to the required superfinishing. Existing capacities no longer suffice, but expansion is associated with costs. In such a situation, contract manufacturing has become a viable alternative.

“Contract manufacturing in the area of superfinishing has been growing for years now for us,” explains Marcel Bosch, process development superfinishing at Nagel Maschinen- und Werkzeugfabrik. “That is why we have expanded our capacities in process development as well as our machinery. We are equipped for all applications, from the smallest rolling elements all the way through to large crankshafts for utility vehicles. We are also always open to new materials and workpieces as well as any quantity desired.”

The automotive area application has always been the most heavily represented at Nagel. However, the superfinishing specialists are also discovering that sectors such as the bearing industry, the aerospace sector and medical technology are growing. In medical technology, the main focus is surfaces for implants. Here, a complete lack of grooves is crucial so that germs have no way of establishing themselves. In vehicle technology, the demand is for a minimisation of CO2 emissions, which requires tribological – friction-optimized – surfaces for the cylinder linings, which are honed, but also for all bearings for crankshafts, camshafts and gear shafts. The magnitude of achievable emission reductions may be minute, but small amounts add up over the entire vehicle. So, if the objective is to reduce friction losses as far as is technologically possible, superfinishing becomes a key technology. Grinding as an upstream process cannot possibly contribute to this objective any further.

“The quality and design of surfaces for bearings is frequently a question of manufacturing philosophy,” says Marcel Bosch. “Some manufacturers tend to produce reflecting surfaces, such as in medical technology, while others produce defined microstructures.”

Some background: Microstructures support the possible formation of a lubrication film. In order to reduce friction or wear and tear when running in a bearing, the process of plateau finishing, for example, gains significance. During this process, the peaks of a rough profile are burnished to plateaus. If the peaks remained, they would be stripped relatively quickly during operation and the result would be the typical wear and tear associated with running in. This is a problem in the event of frequent start-stop cycles in particular. Plateau finishing basically pre-empts the process of running in. Plateau structures are the perfect example of tribological surfaces.

Diligent process development is required so that the result is right in the end. “We don’t simply supply machines and tools; we also develop the processes,” said Bosch. Rz values of around 0.5 μm must be realized. The task becomes even more challenging if certain requirements with regard to dimensional accuracy are added to the mix. One example is spherical bearings. Nagel has a proven solution for this: the dFlex band finishing tool.

“We do not yet know what kind of challenges the future of superfinishing holds. But we do know that the demand for high-quality surfaces, tailored to their function, is growing continuously,” Bosch said.

For more information:

Nagel Precision Inc.

Phone: (734) 426-5650

www.nagel.com

EMAG

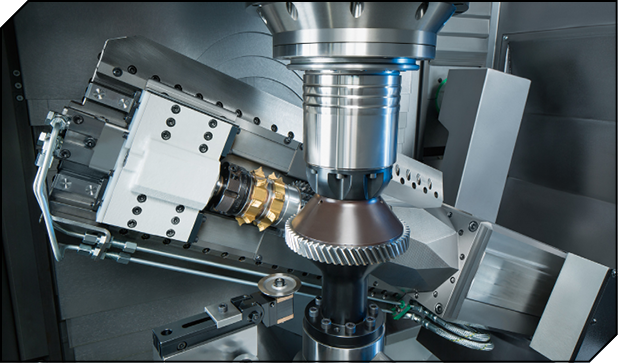

Machining Processes Separated into Categories for Modular Manufacturing Systems

“We have separated the machining process for gears into four easily manageable sub-processes,” says Peter Loetzner, president and CEO at EMAG L.L.C. “In OP 10 and OP 20, we use the VL 3 DUO dual-spindle vertical turning center to machine both sides of the gear blanks. In OP 30, we do the gear hobbing on our VL 4 H gear hobbing machine. The final chamfering and deburring of the finished gear in OP 40 is done on our VL 2 RC or VL 2 CC, depending on what technology is used, Chamfer-Cut or Roll Chamfering.

The pick-up automation system integrated into each modular machine features a parts storage unit for blanks and finished parts, from which the machine is automatically loaded. With this system the machine can achieve chip-to-chip times of only a few seconds. The vertical construction of the machine not only guarantees an ideal chip flow, but also prevents the formation of chip clusters, contributing to a consistently high quality of production.

The interlinking of machines is easy to implement due to the consistent transfer height between the automation systems of individual machines. In addition, the separate energy cabinet allows the use of the new EMAG TrackMotion automation system specially developed for modular machines. The automation system located directly behind the machining area transports the parts and also operates as a flip-over unit, which increases the flexibility of the entire system.

For more information:

EMAG LLC USA

Phone: (248) 477-7440

www.emag.com

BVL Cleaning System

Ensures Reliability without Setup Work for Gearbox Parts

A Spanish supplier for a large German gearbox manufacturer requires a further cleaning system for a new project. The cleaning requirements for the six different and complex aluminum die-cast parts from the automobile sector are very demanding. On the basis of the positive experience that the company has already had with the BvL cleaning system, this project has once again been realized in collaboration with the experienced Emsbüren-based manufacturer and the Spanish partner Edeltec of Barcelona.

A NiagaraDFS basket washing system from BvL forms the basis of the new cleaning solution, which has been equipped with a specially designed retainer in the basket seating. This universal system allows individual parts handling without additional set-up work. The production of six different workpiece holders at BvL means that the basket seating delivers absolute accuracy of fit for the various die-cast components. Replacement of the workpiece holders and components with those from the previously supplied first system is also possible without much set-up work.

After the components have been automatically loaded and fed in via a roller conveyor, the loaded workpiece holder is moved into the cleaning chamber. A combination of spraying, flooding and ultrasound processes ensures a thorough washing and rinsing process in accordance with the preset parameters.

For more information:

DeLong Equipment Company LLC (U.S. BvL Rep)

Phone: (800) 959-5009

www.delongequipment.com

GMTA (U.S. BvL Rep)

Phone: (734) 973-7800

www.gmtamerica.com

Koepfer America

Offers Gear Deburring with CNC Automation

The Tecnomacchine (“TM”) 200 R3 gear deburring machine offers a flexible solution for all job shops with gears up to 7.874" diameter (alternative TM models can accommodate larger workpieces). 5 work stations are utilized: 1 for loading and unloading, 2 for deburring (top and bottom), and another 2 for finish brushing (top and bottom).

This machine produces finished work pieces in as little as 20 seconds (3" diameter parts) or 55 seconds (7.8" diameter parts).

The dual rotary magazines each comprise 8 easily adjustable towers. Each tower can hold parts up to 17.7" high. For example, 283 pieces can be loaded assuming a 0.5" face width gear. This allows the machine to deburr unattended for hours.

The TM 200 R3 is designed for easy setups and adjustments. Changeovers can be completed in under 30 minutes, which minimizes machine idle time.

Both end mills and cutoff wheels can be used for deburring. Brushes are used for finishing with automatic tool wear compensation. With complete control of tool pressures, speeds, and positions, a wide variety of components can be processed.

The machine’s SPC station allows an operator to check quality mid-process. Additionally, for small lot sizes, the machine can also be used in manual-mode. In this case, the SPC station allows easy loading and unloading of a single workpiece.

For more information:

Koepfer America

Phone: (847) 931-4121

koepferamerica.com