Preview of 3D Printing at IMTS 2022

A sneak peek into the booths of JEOL USA, Nidec Machine Tool, and Fortify

Additive Manufacturing (AM) is a space that is maturing at insensate speed—the growth and innovation in materials and technology are staggering. Because of the inherent process of 3D printing, it may allow for a renaissance in the physical design of gears (i.e., integral channels for cooling, lightweighting, and other possibilities) but also holds the potential for gear repairs. Gear Technology spoke with JEOL, Nidec, and Fortify about the technologies they will be on-site to discuss at IMTS 2022.

JEOL USA—#432510 (West Building)

JEOL USA enters a new era of innovation with the introduction of Additive Manufacturing technology for 3D printing. JEOL, Ltd. (Akishima, Japan) has developed and introduced a new Electron Beam Metal (EBM) AM machine that significantly improves quality and manufacturing time to produce stronger and lighter parts for a variety of applications. This new technology currently used in 3D printing production in Japan is now available to manufacturers in the Americas.

Jeol USA’s JAM-5200EBM is an electron beam melting (EBM) powder bed fusion (PBF) machine which is said to significantly improve productivity, quality and reliability to produce stronger and lighter parts for a variety of applications.

Jeol USA’s JAM-5200EBM is an electron beam melting (EBM) powder bed fusion (PBF) machine which is said to significantly improve productivity, quality and reliability to produce stronger and lighter parts for a variety of applications.

What makes the new EBM system, the JEOL JAM-5200EBM, unique in this growing field is JEOL’s decades-long expertise in the development and production of advanced electron optics technology used for research and industrial applications. JEOL is the market leader in electron optics systems involved in a variety of related 3D printing applications from materials characterization to particle analysis in the pre-production stream to imaging, energy dispersive spectroscopy (EDS), and electron backscatter diffraction (EBSD) analysis. Additionally, the JAM-5200EBM’s electron beam technology is solidly based upon JEOL’s 50+ years of experience in the development and production of generations of mask writing and spot beam lithography tools with unique vacuum technology.

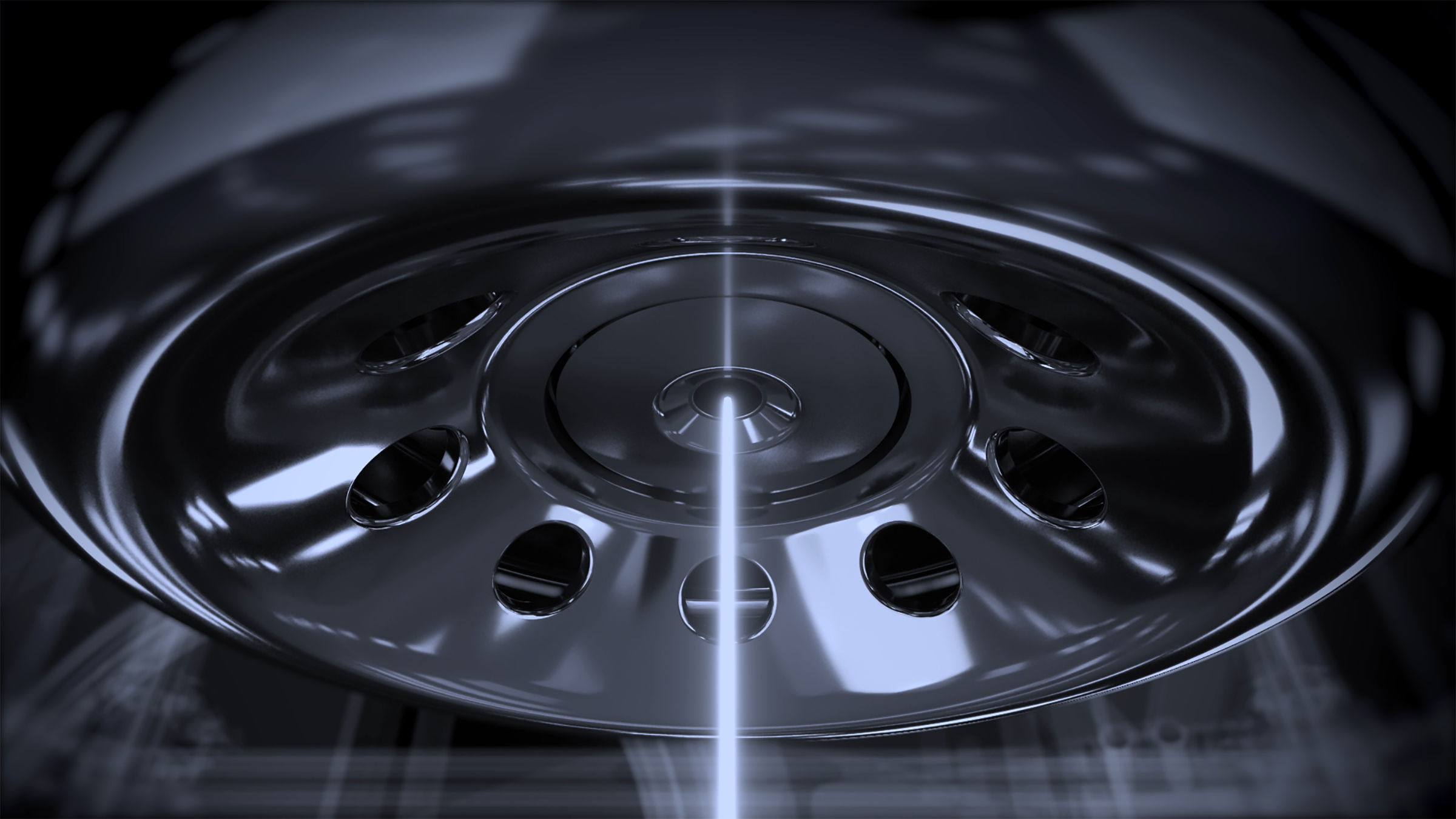

A cross-section view of a titanium metal gear fabricated by the JEOL JAM-5200EBM 3D printer.

A cross-section view of a titanium metal gear fabricated by the JEOL JAM-5200EBM 3D printer.

EBM technology makes it possible to reduce fuel consumption, increase output, reduce cost, improve efficiency, and shorten development time through high-quality and high-repeatability modeling, integration of multiple parts, and weight reduction.

Advantages of JEOL 3D-printing technology include:

- Emphasis on total system uptime, with a long-life cathode over 1,500 hours. The full cathode life and manufacturing quality are maintained in the system’s clean manufacturing environment.

- A clean, helium-free environment and “e-shield” that eliminates smoke events during manufacturing. JEOL’s unique powder dispersal prevention system avoids the scattering phenomenon.

- Focus and spot shape of the electron beam are automatically corrected according to the irradiation position. This technology was developed in-house, based on our market-leading electron beam lithography systems for semiconductor manufacturing.

- Remote monitoring of conditions and manufacturing status.

- Eco-friendly. The system can build multiple parts in a single run.

- Manufacturing capacity of 250 mm (diameter) x 400 mm (height).

- JEOL USA’s extensive service network of over 180 field service engineers will provide after-sales support.

JEOL USA has begun working with pilot sites in the field of additive manuf to integrate 3D printing technology into mainstream production.

Gear Technology: How do you see JEOL’s JAM-5200EBM serving the gear industry?

Robert Pohorenec, JEOL USA President: Many people are surprised when they learn their company is already a JEOL customer. A high technology capital equipment company in business for 72 years has opportunities to provide an array of technical solutions to customers’ challenges. We see the JAM-5200EBM operating in the bay next to the JSM-700HR, for example, our scanning electron microscope which can support a 15-lb. gear, to provide high-resolution imaging and characterization information. JEOL is investigating super steel for tool and gear production. We believe these new alloys will have great advantages for gear and tool manufacturers.

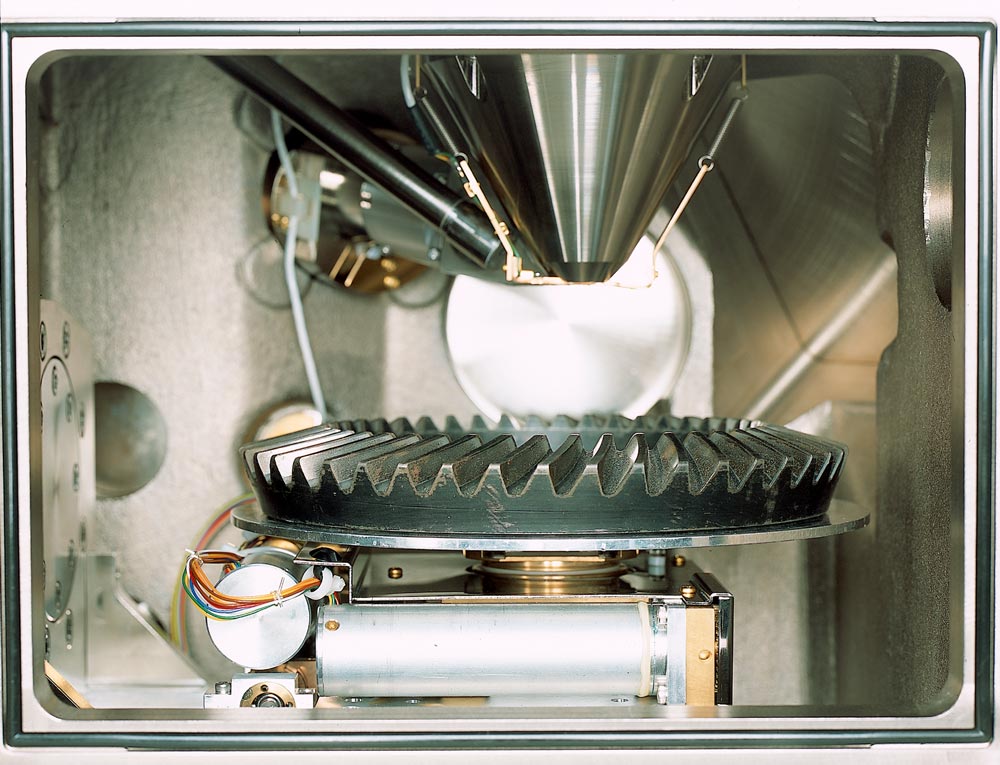

JEOL USA’s JSM-IT700HR is a Scanning Electron Microscope (SEM) capable of loading a variety of gears, tools, and related hardware. Pictured is a Rear Differential Gear from 2 Ton Truck (8”; 12lb).

JEOL USA’s JSM-IT700HR is a Scanning Electron Microscope (SEM) capable of loading a variety of gears, tools, and related hardware. Pictured is a Rear Differential Gear from 2 Ton Truck (8”; 12lb).

GT: Is AM a new direction JEOL? How did this come about?

RP: Additive manufacturing is a new and exciting direction for JEOL. In 2014 we were one of twenty-five Japanese manufacturers and universities that formed the Technology Research Association for Future Additive Manufacturing, or TRAFAM, for the purpose of developing and commercializing next-generation additive manufacturing machines for industrial use. This paved the way for the global product release of our JAM-5200EBM in March 2021.

GT: JEOL has a long history of electron-based technologies, how does that expertise serve to distinguish your EBM solution from other Powder Bed Fusion technologies?

RP: Electron optics and electron beam control are within the “DNA” of the JAM-5200EBM. That inherent IP provides the best-in-class performance in beam control, automation, and emitter lifetime.

GT: Is your Automatic Electron Beam Correction technology a feature unique to JEOL’s EBM solution?

RP: Our Automatic Electron Beam Correction technology was ported over from our JBX E-Beam lithography systems. JEOL released the first computer-operated EBL system in 1967, so there is deep IP even within the subsystems of our EBM solution. Our Automatic Electron Beam Correction technology provides confidence to our users the system will operate as intended for long periods of time without user intervention. Last year during the winter break, one of our EBL users at a National Lab wrote a pattern meeting tool spec for 360 hrs (15 days) nonstop. This Automatic Electron Beam Correction technology is at the core of our reliability and day-to-day repeatability.

GT: Please describe the “scattering phenomenon” and how your e-shield and helium-free environment serve as a solution?

RP: The “scattering phenomenon” occurs when a powder particle does not have adequate adhesion to the build platform. The e-shield prevents energized particles to pass to a powder particle outside the designed build area. Without e-shield, unintended artifacts are created and damage to the system could occur if the “scattering phenomenon” is not controlled. The patented e-shield and our unique scan strategy helps eliminate the “scattering phenomenon” or “smoke events”. This strategy removes the need for helium, an expensive and limited natural resource, and any other gases.

JEOL’s unique helium-free, powder-dispersal prevention system avoids the scattering phenomenon. That not only allows parts to be manufactured in a clean space at a low-cost, the surface of the cathode is also less susceptible to damage, allowing the electron beam to remain stable.

GT: What role do you see AM playing in the gear industry as the technology achieves more mainstream adoption?

RP: We think AM can make the gear industry more efficient and bring new solutions to its customers at a faster rate due to the inherent advantages of AM. There are cases where traditional manufacturing and additive manufacturing are complementary, giving gear manufacturers the possibility to mix and match these technologies for their optimum solution.

The long-life cathode, which lasts over 1,500 hours, can greatly reduce downtime for cathode replacement. The secret is JEOL’s original vacuum technology, developed in the manufacturing of electron beam related equipment.

The long-life cathode, which lasts over 1,500 hours, can greatly reduce downtime for cathode replacement. The secret is JEOL’s original vacuum technology, developed in the manufacturing of electron beam related equipment.

We believe our long history of development and production of advanced, field-proven electron microscopy and electron beam technology, combined with JEOL’s extensive service and support network, is an opportunity to integrate quality and reliability into the employment of this novel technology.

Nidec Machine Tool—#237036 (North Building), #338252 (South Building)

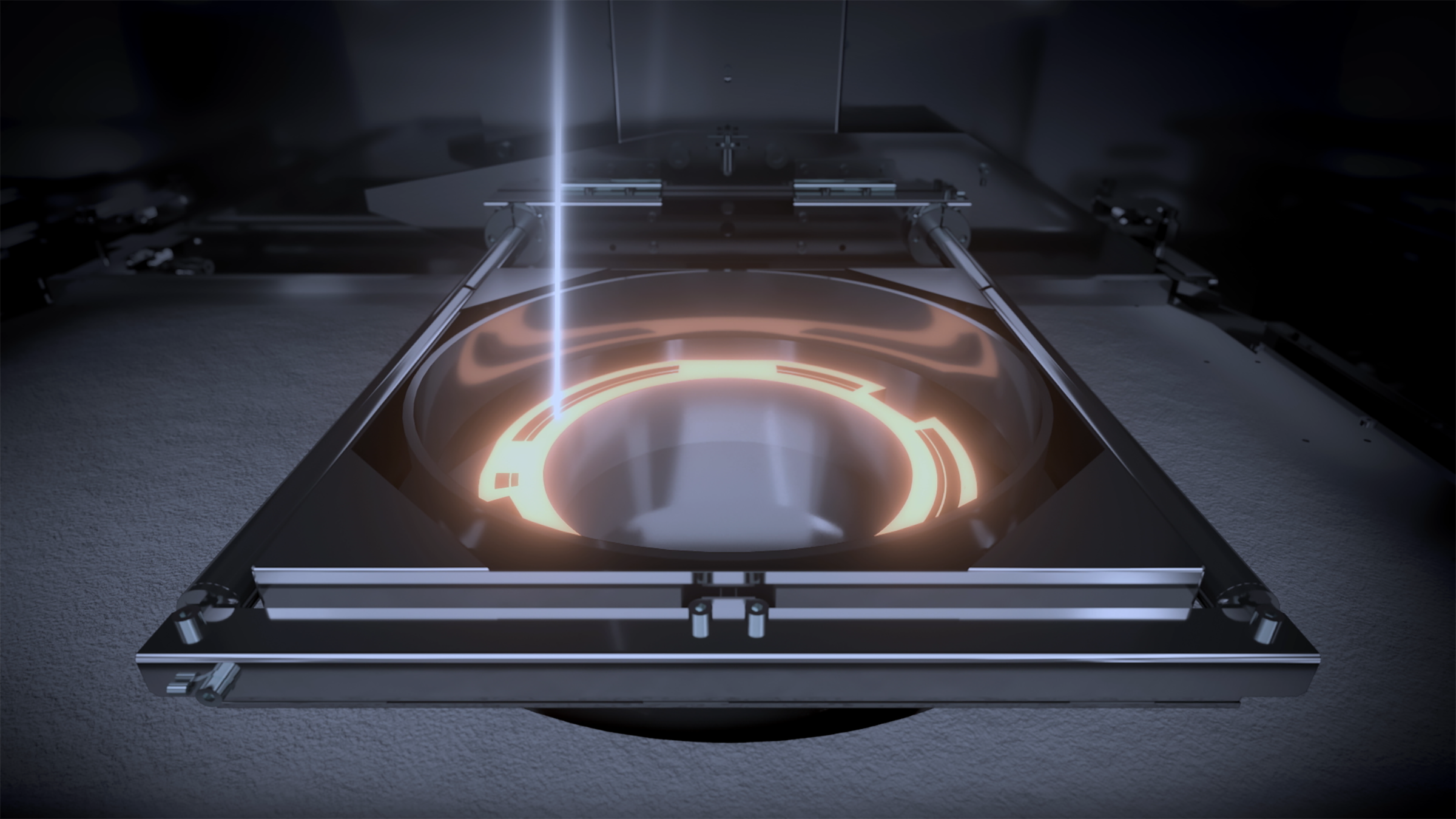

DED, or directed energy deposition, as implemented in the Nidec LAMDA 3D printing systems, utilizes a powerful focused laser beam to melt powdered metal that is supplied to the build area by a nozzle. As the laser heats the powder, it melts and sinters to the baseplate or layer below.

There are three powerful technologies integrated into the LAMDA’s state-of-the-art control. First, by monitoring and controlling the laser power in real-time, the size and temperature of the melt pool is constantly controlled to permit accurate deposition and full integration of metal onto the part being printed. This monitoring system also provides a fully verified quality control record of the build.

State-of-the-art local shield nozzles with enhanced shield performance. The optimized shield gas jet expands the shield region area up to 45 times the conventional size. The local shield function eliminates oxygen in the environment around the molding process to prevent the oxidation of molten metal.

State-of-the-art local shield nozzles with enhanced shield performance. The optimized shield gas jet expands the shield region area up to 45 times the conventional size. The local shield function eliminates oxygen in the environment around the molding process to prevent the oxidation of molten metal.

Secondly, when printing materials that are reactive with oxygen, inert argon gas is used by the LAMDA Local Shield. This excludes oxygen from the melt pool and allows large components to be 3D printed without the need for an expensive atmospheric chamber. This also greatly reduces the cost of operation by not needing to purge large quantities of this inert gas.

The third important technology brought to additive manufacturing detects potential problems before the process fails. To build large items defect-free, LAMDA has deep learning AI for anomaly detection. The machine knows and can detect many anomalous patterns at installation, and the machine will “learn” additional new anomalies as they occur. This image processing occurs at 300 images per second, which is faster than the speed of the CNC control unit.

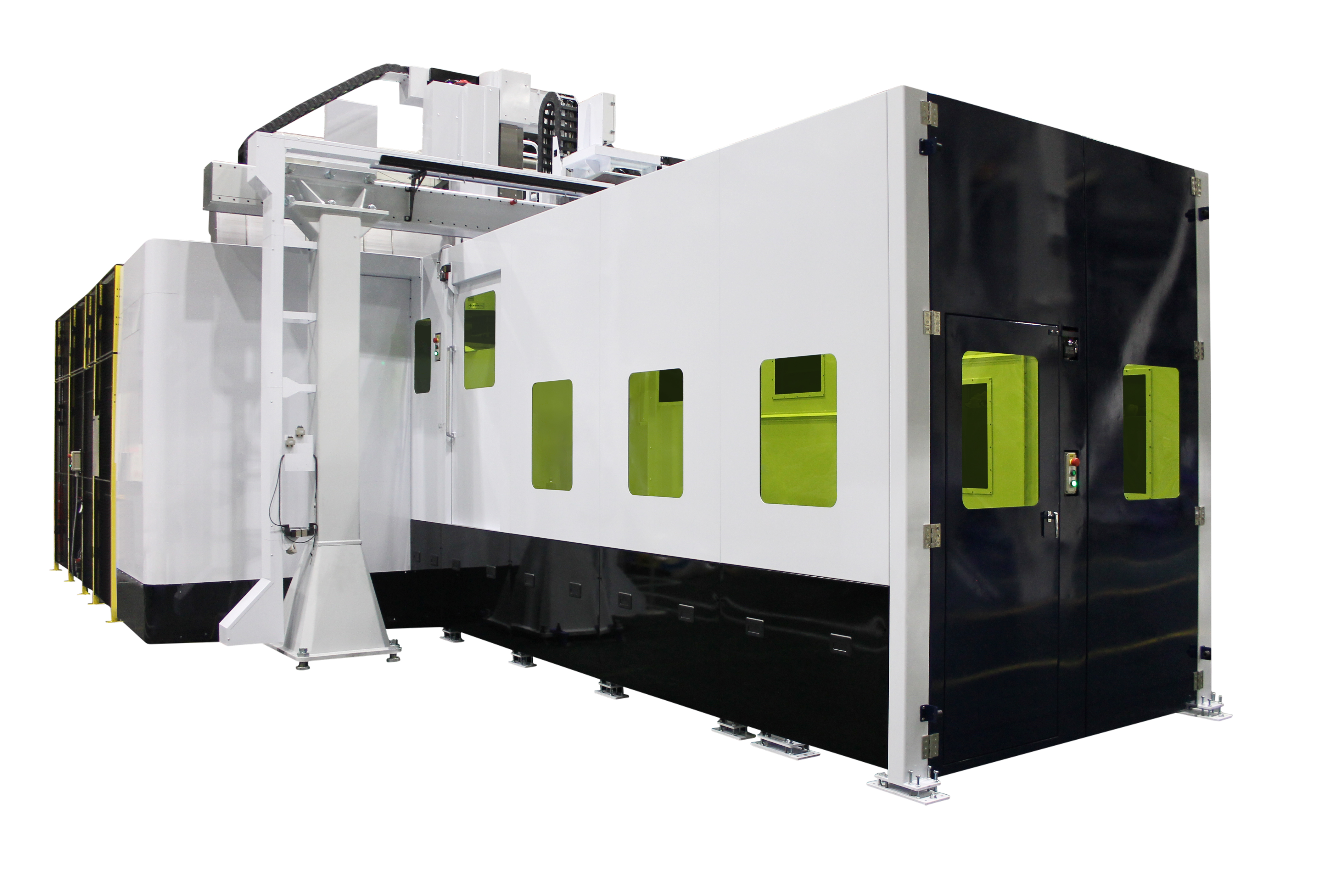

Nidec Machine Tool’s LAMDA2000 3D metal printer is a direct energy deposition additive manufacturing system.

Nidec Machine Tool’s LAMDA2000 3D metal printer is a direct energy deposition additive manufacturing system.

Applications for DED include uses beyond full 3D printing builds. The ability to apply material to an existing part is a valuable repair option for expensive, hard-to-make, and long-lead-time components. The ability to use two different materials, for example, titanium and Inconel, on the same part opens even more possibilities for repair and solving problems.

The range of materials that can be used with DED is quite amazing. Stainless steel, maraging steel, Inconel, titanium, and even aluminum can be used without an atmospheric chamber.

For gear manufacturing and gearbox repair, having the ability to add material back to a large (expensive) gear or shaft can be a game-changer. Printing workholding components, robot grippers and a vast array of tooling is another example of DED providing value to the gear-making community.

nidec.com/en/nidec-machinetool

Fortify—#433114 (West Building)

Fortify developed Digital Composite Manufacturing (DCM) to unlock new material properties that cannot be achieved with today’s 3D-printed photopolymers. They achieve these properties by suspending and aligning Functional Additives (particles and reinforcing fibers) in a resin matrix during printing. Fortify’s open materials platform allows for a wide range of material properties that can be architected to meet the most stringent application needs.

A 3D-printed gear made with Fortify's HTS resin.

A 3D-printed gear made with Fortify's HTS resin. In DCM, functional additives must be uniformly distributed to achieve consistent material properties. Fortify’s Continuous Kinetic Mixing (CKM) addresses this issue by blending, recirculating, and heating the resin-additive matrix as required throughout the printing process.

Fortify partners with the world’s leading chemical companies to architect specific material properties based on the need of a particular application and solve printability challenges that are barriers to commercialization on other photopolymer platforms:

High Deflection Temperature (HDT) and high strength and stiffness ceramic-fiber reinforced photopolymer tuned for use in tooling applications.

Low-loss dielectric materials for use in high-bandwidth, high-frequency communications systems.

Technical ceramics with low shrink for high-temperature and radio-frequency applications.

High-temp electrostatic discharge (ESD) material for tools, jigs, and fixtures that can be placed directly into a solder reflow oven.

Resins with 10x the thermal conductivity of any other photopolymer with electrical insulation for sensitive heat transfer applications.

Fortify's FLUX Series printer lineup.

Fortify's FLUX Series printer lineup.

Fluxprint is Fortify’s fiber alignment module. In DCM, during the printing of each layer, a magnetic field is applied across the build area. This aligns all fibers throughout the layer in the target orientation. Individual regions of this layer are then cured with UV light. This locks the orientation of fibers only in those regions. This process of orienting and locking fiber is repeated as needed within each layer and for the subsequent layers. This unique ability to control fiber orientation throughout a part allows for precise tuning of material properties and is unprecedented in any manufacturing technology.

Ben MacDonald, Senior Applications Engineer, said the following about Fortify’s high-temperature and strength (HTS) resin, a particularly strong material candidate for gear applications: “HTS is a resin that is uniquely suited for printing gears due to its strong wear resistance properties which enable gears printed in HTS to significantly outlast alternate materials. This wear resistance is paired with a high HDT allowing for these gears to operate in harsh conditions while maintaining structural integrity.”