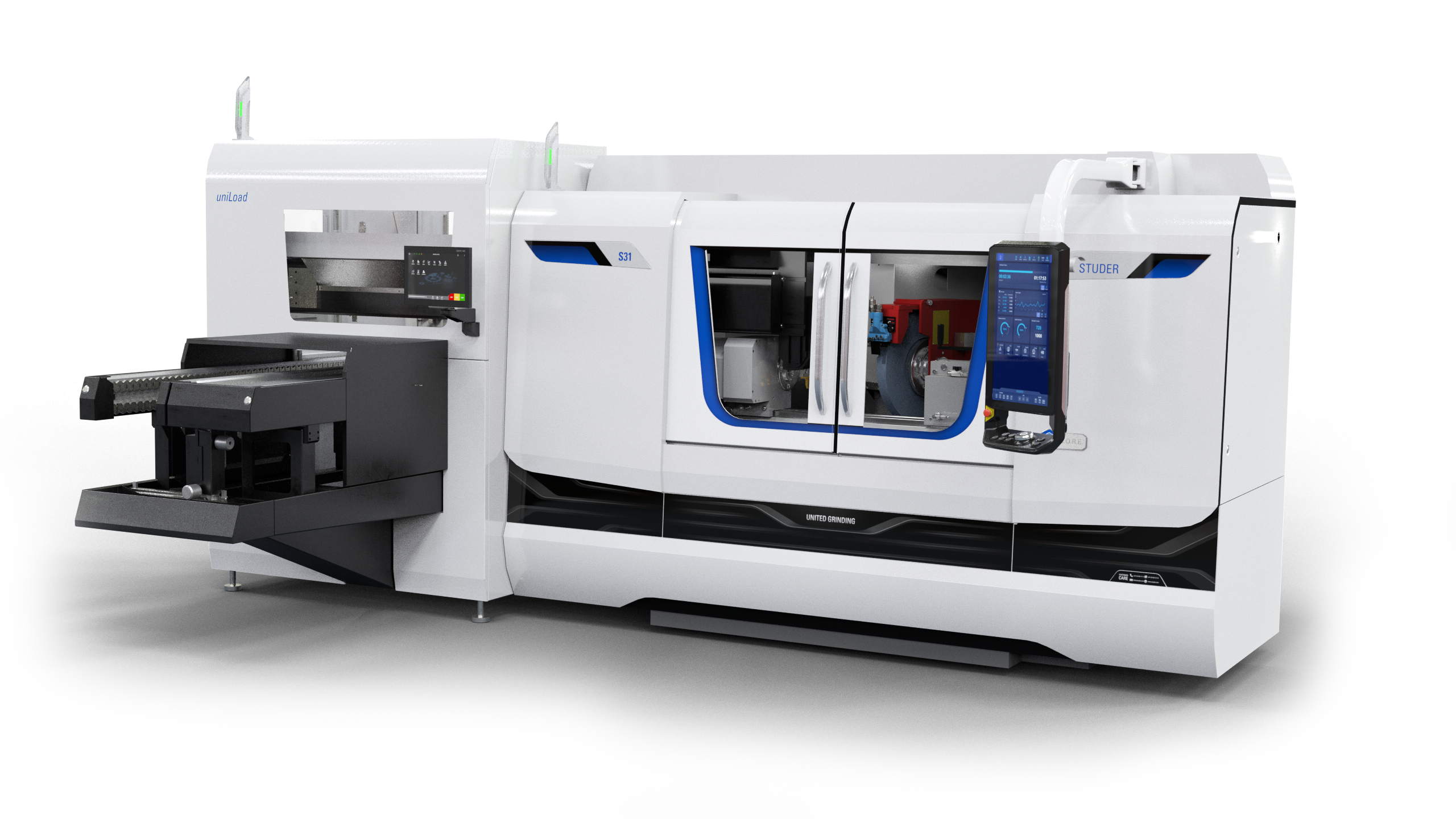

STUDER Introduces the UniLoad Loading System

STUDER focuses on universality and speed with the uniLoad loading system. The automatic loading system enables users of the S31 and S33 external cylindrical grinding machines to increase quality and productivity.

Thanks to its modern and intuitive control, the uniLoad system is so easy to operate that no special programming training is required. The control was developed by Wenger Automation and continues the STUDER operating philosophy. The user only needs to know the dimension and weight of the workpiece in order to use the loading system. The set-up wizard then guides the user conveniently through the necessary steps to start the grinding program.

STUDER uniLoad is offered based on a linear portal cell with two parallel grippers and is suitable for shaft components up to a length of 350 mm (13.8”) and a diameter of 100 mm (3.9”). It thus covers a large proportion of the component ranges produced on these machines. The parts are supplied via a standardized, adjustable V-belt. The housing for the base module, which is provided with a loading hatch as standard, has been adapted to suit the machine design and enables safe and clean operation of the system.

STUDER uniLoad is currently suitable for distances between centers of 650 mm (25.6”) and 1000 mm (39.4”). With the racks at full capacity, the loading system is docked onto the machine and enables automated processing of around one hour. In the case of workpieces with an external diameter of 34 mm (1.3”) and a gripper diameter of 22 mm (0.9”), 50 parts can be loaded automatically. The look of the loading system is reflected in the aesthetic design of the machine, and as a standard product enables quick response and delivery times. Customized solutions are also possible. In addition, uniLoad is expandable so future requirements can also be met.

The uniLoad, equipped with a Siemens Simotion control, gripper with quick change jaws, and an intuitive 15-inch operating panel, is the latest cylindrical grinding innovation from STUDER.