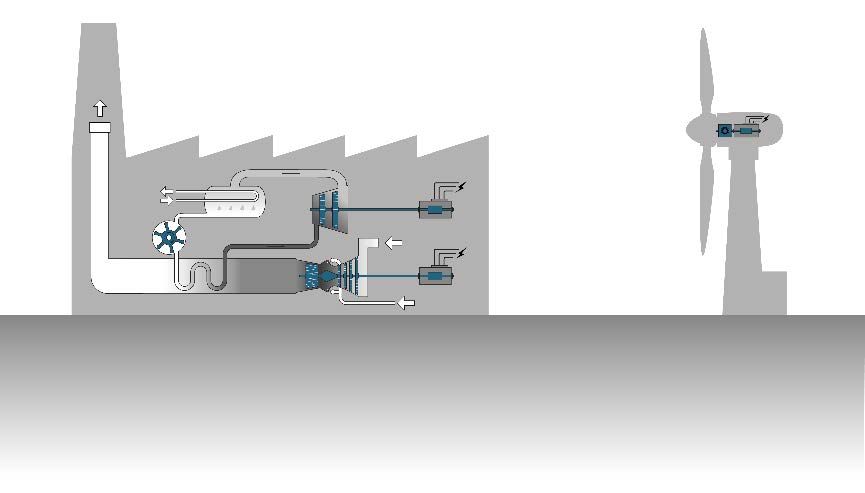

Complete Machining of Components for Small Power Plants

Energy production, energy efficiency, energy crisis—the topic of energy concerns us today more than ever. The growth of clean energy technologies is relentless, companies want to manage their energy budgets efficiently and the carbon footprint of products will probably become a sales criterion soon.

Up to the end of the 19th century, energy was generated by means of human and animal power. The rapid progress brought about by the industrial revolution meant that faster, more efficient solutions were found. We’re talking about all kinds of special small power plants.

WFL is also establishing itself in this sector with the complete machining of key components for small power plants: turbine, gear and generator shafts as well as valves and pump wheels have the highest shape and position tolerances and place high demands on their machining process. For the efficient production of such workpieces, a Millturn machine masters the necessary special technologies such as the milling of special profiles or large gears as well as the grinding of shaft parts including concentricity and roundness measurement—all in compliance with the highest precision requirements.

The Machining Process

The untensioned blank in the generator shafts is often pre-turned and turned into a Millturn with welded-on bars. As an alternative to welded-on bars, some generator shafts are also made from solid material. One of the most important aspects of machining the welded-on bars is ensuring that the blank is aligned in the circumferential direction in such a way that the longitudinal grooves are inserted in the center of the bars. Thanks to the WFL measuring cycles, the measurement of this blank is fully automated, with it even being possible to determine and correct welding errors. In the shaft area, beveled ø 60 mm holes must be inserted, which meet the ø 100 mm center hole at a depth of approx. 500 mm. All holes can be inserted in the Millturn without any tools, with very elegant rounding of the edges of the holes being carried out too. The precise outside diameter of the bars that is to be machined is finished in IT7 quality by means of turn-milling. Bearing seats on the pins are rotated with maximum precision and subsequently rolled. The WFL in-process measuring guarantees process reliability, even with IT6 quality.

Savings Guaranteed

The potential savings when machining generator shafts in a Millturn are considerable compared to sequential manufacturing on different machines: a full 60% can be saved by complete machining in the process chain. In the case of set-up time, the savings are as high as 80–90 percent.