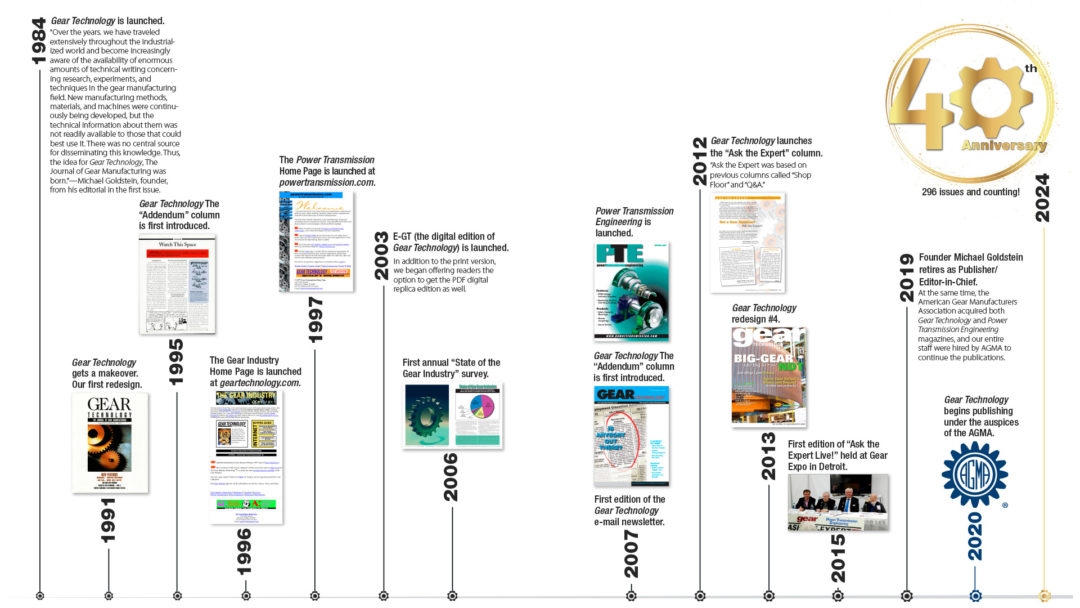

Celebrating 40 Years

Gear Technology’s Milestones and Memories

Gear Technology began with the May/June 1984 issue. Forty years later, we’re still going strong! Please join us in looking back at some of our milestones and celebrating what makes this publication truly unique in the marketplace.

Don’t miss some of the related articles throughout this issue, including my own 30-year (and counting!) journey with the publication (p. 8), the history of how Gear Technology got its start from our founder, Michael Goldstein (p. 10), and an engineer’s perspective from our longtime technical editor and contributor Chuck Schultz (p. 11).

We’re extremely grateful for the support we’ve received from our readers, advertisers and contributors. None of this could have been possible without all of you.

Why Do You Read Gear Technology?

We asked our readers to fill out a one-question anonymous survey: Why Do You Read Gear Technology? We received almost 200 responses, including some of the highlights reprinted here:

“I read Gear Technology for updates on new gearing applications, new machinery available to the gearing world and promotions within companies. Great source of information.”

“I work in maintenance in a steel mill and need to know about many aspects in the production of gears for our needs.”

“For technical articles, updates. [Information about] new technologies like skiving.”

“I read Gear Technology to stay updated on new products and technology related to gear manufacturing…I need to understand how gears are manufactured and how any potential new technology could affect our products and our approach.”

“For interesting topics related to gear technology (drive systems, gear calculations, failure mechanisms, etc.)”

“When I entered the world of gearing as a gear engineer in 1977, I was drawn to the mathematics behind every design and manufacturing process. My education was in mathematics, but I never would have anticipated using it in this technical field. We had our already established formulas and design criteria based on the years of experience in the heavy-duty truck transmission and axle business. But when the first issue of Gear Technology came out, it opened up a whole new world of research and new ideas. I still have some of the early publications, but I wish I had kept them all. Now…working as a consultant in the manufacturing world, I am back to reading most articles and using the advertisements as resources to investigate. I have encouraged all the engineers I work with to subscribe and it is fun to talk with them when they receive their first magazine. Thank you for doing such a great job for the gearing professions. By the way, I still have the set of Michelangelo gear sketches that you offered to subscribers in your first year in circulation. Congratulations on your first 40 years!”

“Because it keeps me informed about the latest technology and gear news. It is a really interesting and amazing magazine.”

“For me, [it is] the best publication with respect to the gear industry for all the technical pieces it includes. Plus it keeps you up to date with the latest technologies available from the industry’s principal suppliers.”

“I read Gear Technology magazine to get both a broader view of the gear industry and industries that use gears, as well as to gain a better understanding of engineering concepts that I did not learn from my days in college.”

“To open my mind to other types of industries and technologies developed in order to implement them or develop something alike for the off-road industry.”

“Tracking the evolution for gear manufacturing and gearbox design. To understand the evolution of new technologies and what this can mean for our applications.”

“Gear Technology is one of the world’s most renowned magazines in the field of transmission and gear technology and therefore a must for every gear specialist. I have been reading Gear Technology for more than 15 years.

“To understand better what is going on in the gear industry.”

“It gives me a perfect overview of what happens in the gear market.”

“Gear Technology is the international reference point for gear manufacturers.”

“I value the technical content; it is high quality!”

“It is the greatest knowledge available about gears.”

“For the love of transmissions! More soberly, to return to basics and to advanced technologies at the same time.”

“I am working in a company which is related to gear manufacturing, and Information from the magazine helps to understand new technology and research topics, and to exchange knowledge.”

“Because it is very helpful with staying informed about what is new in gear manufacturing.”

“Gear Technology always delivers interesting articles on gear manufacturing with a lot of technology information. I find it to be a source of knowledge and very informative and will continue to read it due to the rich content.”

“To be aware of products, people and events in the gear industry.”

“Gear Technology provides valuable information on gear design from top to bottom, which enhances our knowledge and also helps us to update our knowledge on new technology.”

“To maintain knowledge of latest in gear manufacturing, inspection and analysis methods.”

“For my pathway as gear design engineer. Gear Technology is a great knowledge source for any engineer involved in the gear field.”

“It is a good way to keep updated with the latest technologies and trends in the gear world!”

“I enjoy keeping up with what is going on in the gearing world. This is one of the few publications that is dedicated to this technology field. I wish your publication many more years of success.”

“Innovative gear engineering articles and … insightful interviews from domain experts gives me the passion to read GT...always...”

“I enjoy the technical articles and keeping up to date with the latest in technologies available.”

“To learn about gear production technology and industry trends.”

I read Gear Technology because I work in a factory producing gears, and I am interested in new technology to manufacture gears. Also I need to know about terminology of different kinds of gears and basic principles of manufacture.”

“It is a very powerful tool and source of information for all the people involved in gear design, manufacturing, field service, consultants and for all the users of mechanical power transmission equipment.”

“Gear Technology is very helpful to my job in gear manufacturing technology.”

“I read it because it updates me on industry news and also provides technical information of interest to me.”

“The technical articles have proven very informative and useful over the years.”

“I have been engineering and designing gears and gear units for 50+ years, Gear Technology is a wonderful resource for ideas and new technologies.”

“To know about the new developments and tendencies of research and industry.”

“I began reading Gear Technology in the 1990s. I first read Bob Errichello’s articles ‘The Lubrication of Gears’ parts 1, 2 and 3. I had to chase down copies of Gear Technology and make photo copies as the online archives did not exist. I have been a subscriber ever since. I have used the information from many of the articles as starting points to improve my knowledge of gear design. I have then taken AGMA courses with both Bob Errichello and Ray Drago among others whose articles appeared in the magazine.”

“The best magazine for the gear industry.”

Having spent my career as a designer for industrial and marine high speed/high power gearboxes, I like to keep myself updated and abreast with developments within the industry. Gear Technology certainly provides this. Thank you so much. I greatly appreciate reading it.”

“Great technical content, industry news, editorials and now the ties with AGMA are a great boon. Been reading 30 or more years.”

“Gear Technology magazine gives lots of information on design, manufacture and inspection of special purpose gearboxes. It also gives references to AGMA and ISO specification for design of special purpose gear drives and manufacturing practices. Gear Technology is a top-class magazine for gear drive design and manufacture.”

“To keep up with the latest technology relative to gear manufacturing and metrology.”

“While I have not been directly involved in gear manufacturing for many years (except that, from time to time, one of our vendor-facing engineers will say, “Hey, I hear you’re our gear guy!) I am still an assiduous reader of Gear Technology. By any measure, the manufacture and inspection of geared components is the most challenging and, if you want to be ahead of the curve in manufacturing, you must keep abreast of the gear industry.

“Informative with technical information in easy-to-read format featuring timely topics. Enjoy reading the Publisher’s Page and Addendum. The ads give a great idea of what’s available in the gear marketplace.”

“Extremely informative. Great for learning new techniques and gear machines.”

“Because it gives me useful information about the state of the art in gear technology. It gives me information about suppliers and specialist gear engineers…I have fun reading the magazine at home.”

“Refresh and update old knowledge. Understand and keep current with new and future technologies. Keeps me a step ahead of my peers and competition.”

“The definitive, and most authoritative, source for all things related to the gear industry.”

“I read Gear Technology magazine as it keeps me informed about the latest developments in the gear industry. It provides me with updates on cutting-edge gear technology, introduces me to new products, and gives me insights into the most recent research. It’s a valuable resource for staying up-to-date in this field.”

“The technical contents, especially those with formulas, get saved for future reference.”

“It is the source of essential information pertaining to gear production, inspection, application and performance.”

Thank you to all of our advertisers, without whose support, none of this would be possible. Our 40th anniversary issue sponsors include: | |

AFC-Holcroft B&R Machine and Gear Corp. Bevel Gears India Cattini North America DTR Corp. DVS Group EMAG LLC Ever Sharp Tools Federal Broach Forest City Gear German Machine Tools of America Gleason Corporation Goldstein Gear Machinery Hobsource IMTS | Involute Gear & Machine ITW Heartland Kapp-Niles KissSoft Klingelnberg Liebherr Machine Tool Builders Mcinnes Rolled Rings Metal Powder Industries Federation Nidec Machine Tool America Nordex Inc. Norton | St. Gobain Oelheld US Inc. Spiroid Gearing Star SU LLC |