Items Tagged with 'collaborative robots'

ARTICLES

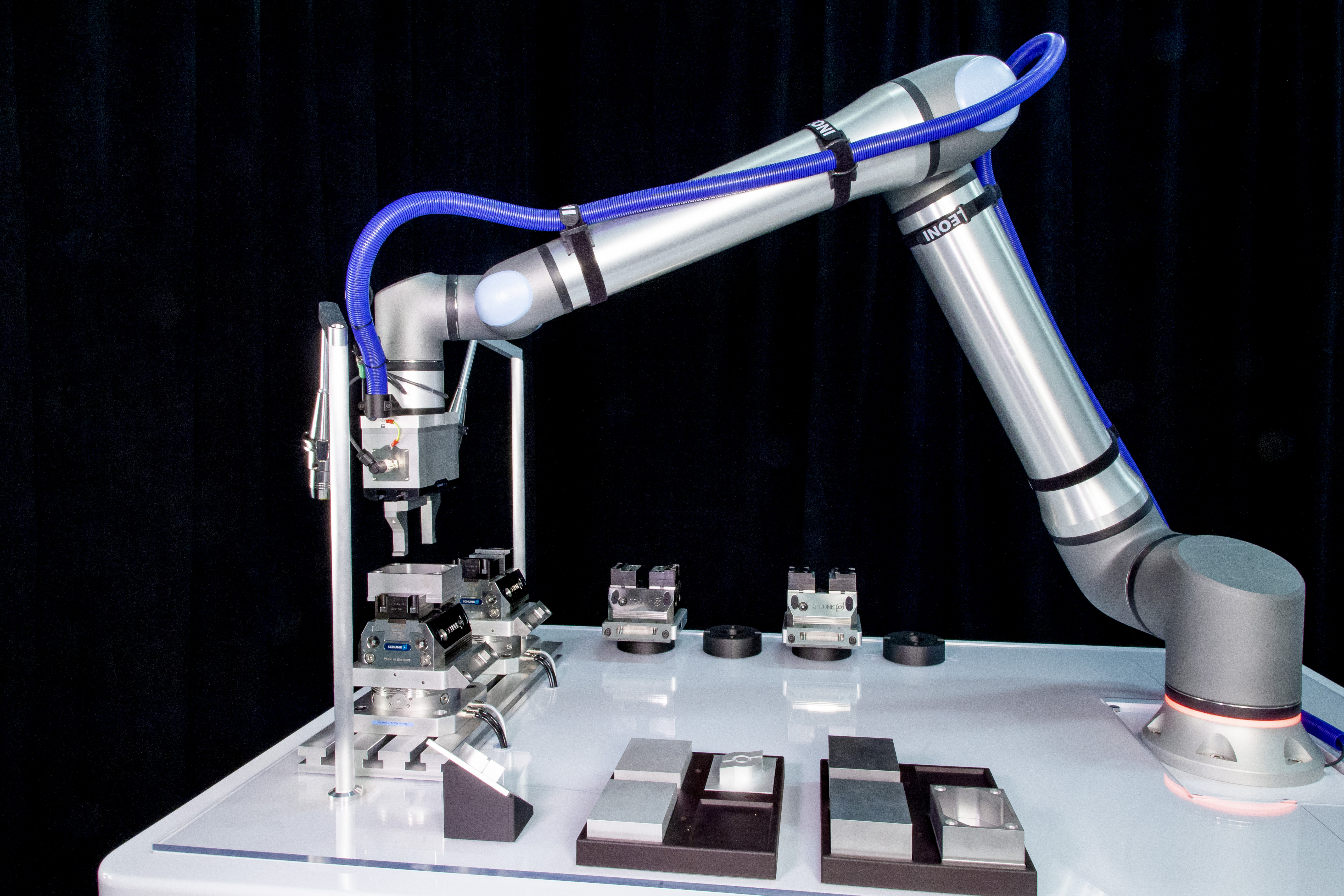

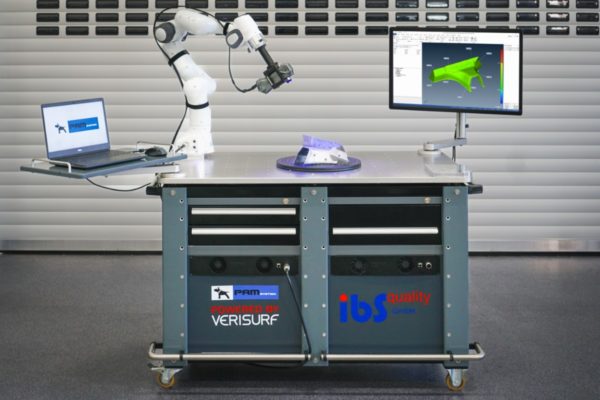

Stäubli Robotics to Show New Manufacturing Technologies at IMTS 2022 in Chicago

Robotic machine tending, collaborative mobile robotics and other technologies for optimizing process efficiency and boosting productivity

Read More