GWJ Technology GmbH

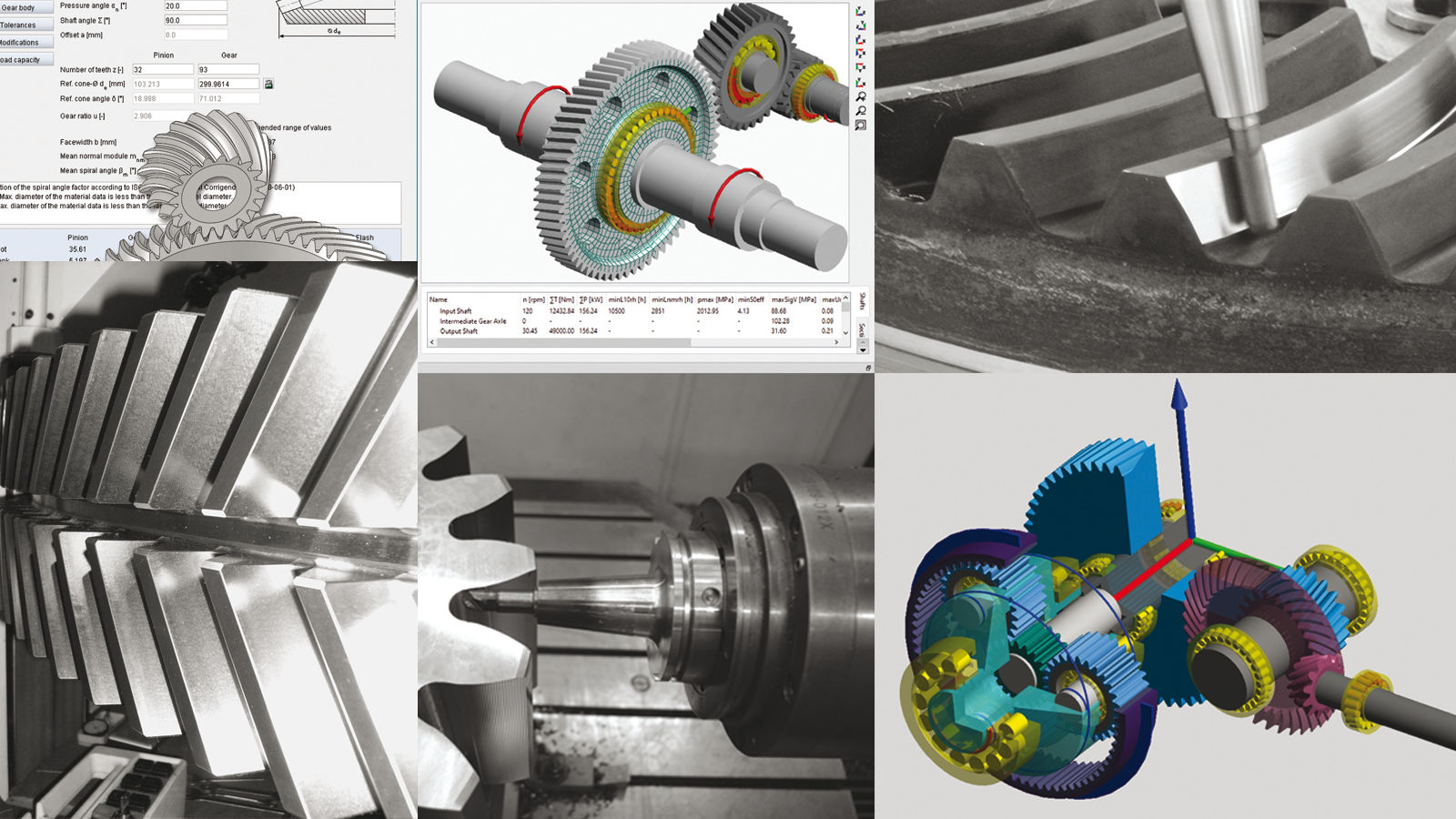

Our scalable product portfolio covers a wide range of applications:

- Standard software for machine elements such as shafts, gears, bearings, involute splines, parallel keys, interference fits, and more

- Web-based solution eAssistant and desktop application TBK

- Powerful 3D CAD integrations for seamless design workflows

- SystemManager – complete gearbox design as a true multi-shaft system

- GearEngineer – advanced software for gear manufacturing via 5-axis milling, forging, molding, additive manufacturing, and more

Your Benefits at a Glance:

- Save time with intelligent layout features, automatic recalculation, and convenient undo/redo functions

- Work efficiently with intuitive, user-friendly interfaces

- Accelerate development with perfect integration of calculation and 3D CAD

- Reduce costs through our comprehensive, cost-effective web solution

- Optimize gears according to the latest international standards

- Speed up product development with complete gearbox design capabilities

- Reuse gear data seamlessly from design to manufacturing to quality control

- Unlock new manufacturing possibilities, such as 5-axis milling, forging, molding, or additive manufacturing – based on accurate digital twins

- Expand your know-how with training and support from our highly experienced engineers

GearEngineer delivers precise, real 3D geometries for gear production on multi-axis CNC machining centers or via alternative manufacturing methods. The digital twin includes tolerances and micro-geometry and is based on a mathematical simulation of the manufacturing process – fully analogous to traditional gear cutting methods. GearEngineer is among the world’s leading and award-winning software solutions in this specialized field.

With customers in over 45 countries across 6 continents, GWJ Technology is one of the global leaders in calculation software for mechanical engineering – especially for gears and gearboxes.