Items Tagged with 'grinding'

ARTICLES

Key techniques for optimal surface finish and gear quality

Read More

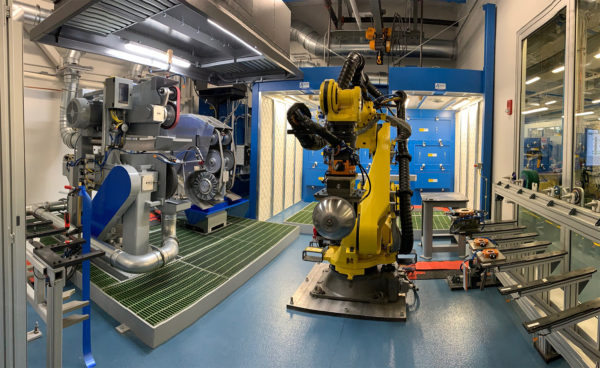

ARGUS “Swarm-Based” Gear Grinding Expertise

A process and machine component monitoring system

Read More

Process Variables for Gear Grinding

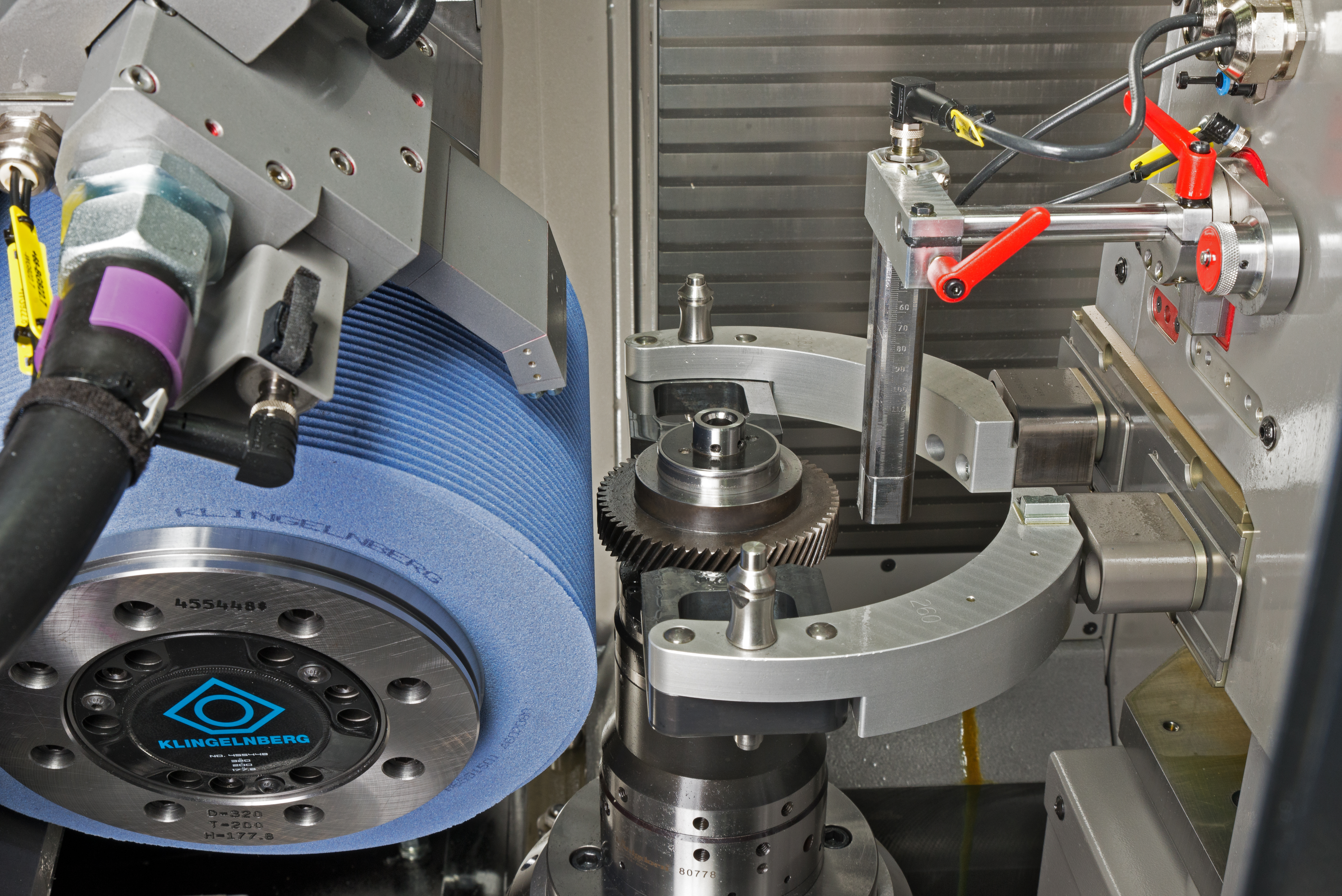

Tremec Offers Latest Transportation Technology with Assistance from Klingelnberg Speed Viper

Read More