Nanotechnology in Electric Vehicles

(This article was a sidebar to "The Numbers Game," which appeared in the May 2022 issue)

Like the charged power suit worn by Black Panther of Marvel Comics, UCF researchers have advanced NASA technologies to develop a power suit for an electric car that is as strong as steel, lighter than aluminum and helps boost the vehicle’s power capacity. The suit is made of layered carbon composite material that works as an energy-storing supercapacitor-battery hybrid device due to its unique design at the nanoscale level. The development could have applications in a range of technologies that require lightweight sources of power, from electric vehicles to spacecraft, airplanes, drones, portable devices and wearable tech.

“Our idea is to use the body shells to store energy to supplement the power stored in batteries,” says study co-author Jayan Thomas, the team leader and a professor in UCF’s NanoScience Technology Center and Department of Materials Science and Engineering. “The advantage is that this composite can reduce the weight of your car and increase the miles per charge,” he says. “It is as strong as or even stronger than steel but much lighter.”

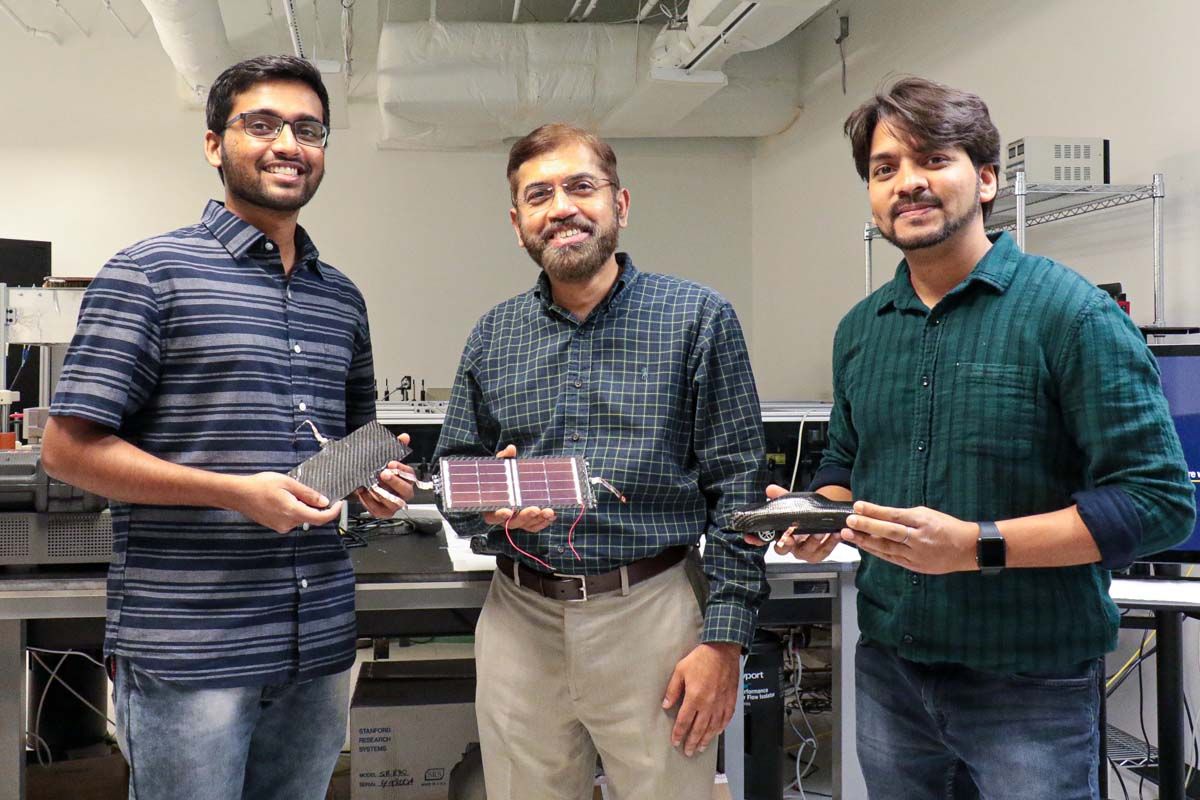

University of Central Florida researchers Kowsik Sambath Kumar, Jayan Thomas, and Deepak Pandey show the lightweight, supercapacitor-battery hybrid composite material they’ve developed. Kumar and Pandey are UCF doctoral students, and Thomas is a professor in UCF’s NanoScience Technology Center and Department of Materials Science and Engineering.

University of Central Florida researchers Kowsik Sambath Kumar, Jayan Thomas, and Deepak Pandey show the lightweight, supercapacitor-battery hybrid composite material they’ve developed. Kumar and Pandey are UCF doctoral students, and Thomas is a professor in UCF’s NanoScience Technology Center and Department of Materials Science and Engineering.

The material, when used as a car body shell, could increase an electric car’s range by 25%, meaning a 200 miles per charge vehicle could go an extra 50 miles and reduce its overall weight. As a supercapacitor, it also would boost an electric car’s power, giving it the extra push, it needs to go from zero to 60 mph in 3 seconds.