Innovative Workholding Solutions for Gearing Technology at IMTS 2022

Clamping systems save time and stabilize manufacturability

Workholding solutions increase throughput which generates uptime because they greatly reduce setup and changeover times. Operators can change workpieces in a highly repeatable manner which significantly increases the quality of the finished part. The primary function of streamlining production is to develop a workholding solution that optimizes the machining of multiple parts at once while maintaining tight tolerances. Below you will find a cross-section of companies that will be showcasing their approach to workholding systems at IMTS from Sept. 12–17 at McCormick Place in Chicago.

Gleason Corporation—#236909 (North Building)

Gleason Hydraulic Workholding Systems

Gleason Hydraulic Workholding Systems are an attractive alternative to traditional mechanical systems, offering benefits for many bore and shank clamping applications. With different expansion zones hydraulic workholding systems easily accommodate to multiple gear stacking and different bore diameters. They deliver a powerful and consistent clamping force with uniform expansion over the complete chucking length, making them an ideal solution for clamping thin-walled parts. Gleason Hydraulic Workholding Systems work in a completely enclosed system, impervious to contamination limiting maintenance downtime when compared to exposed mechanical systems. Depending on the application Gleason Hydraulic Workholding Systems deliver accuracy and repeatability of up to of 1.3 microns (0.00005") TIR or even better. Gleason Hydraulic Workholding Systems are available for standard machining, gear manufacturing like hobbing or skiving, and tool sharpening work.

Gleason Gear Pitch Line Fixtures

Gleason Pitch Line Fixtures are a great way to improve final accuracy between gear datums and gear pitch. Undesirable runout results from the heat treatment of gear and other manufacturing processes which may cause distortions. Pitch line fixtures can be used in applications such as hard turning, grinding and inspection. Depending on the application Gleason offers Pitch Line Fixtures with gear member accuracy of up to 5 microns (0.0002") relative to the bearing journals or bores. Gleason also offers hydraulic quick-change solutions for part-to-part quick changeovers.

Quik-Flex Plus—Modular Quick-Change Workholding

Now accommodating a changeover for different workpieces can be done with a new module that’s installed and removed in just seconds, with only a single tool, and by even a novice. Quik-Flex Plus is so simple and effective that even non-operator contestants in Gleason’s tradeshow demonstration challenges have routinely removed and installed Quik-Flex in under 10 seconds. For gear manufacturers running small and medium batch lots throughout the day, this can mean a savings of an hour or more in spindle time. The ease of changeover when utilizing Quik-Flex Plus can greatly support less skilled machine operators and toolmakers, which are becoming harder to find.

Hainbuch America—#431636 (West Building)

The Hainbuch Maxxos T211 is a mandrel with hexagonal geometry for added process reliability and maximum cutting performance.

Hainbuch Maxxos T211 is a mandrel with a hexagonal pyramid shape instead of a round taper, designed with stringent manufacturing requirements and process reliability in mind. Hainbuch has acted in response to demand from specific areas that have been growing year by year. Users are requesting mandrels that deliver higher performance as well as process reliability. The result is called Maxxos. The segmented clamping bushing with hexagon inside shape fits perfectly onto the clamping pyramid and enables maximum cutting performance. The lubrication, combined with its tightness ensures a very constant production flow and as a result, achieves maximum reliability. Customers who value process reliability and maximum torque transmission will be delighted with the Maxxos T211.

Thanks to the hexagonal pyramid clamp, maximum torque transmission can be achieved. Up to 155 percent more transmissible torque and up to 57 percent higher bending stiffness compared to the classic Mando T211 mandrel. This makes it possible to achieve higher process parameters and consequently improve the yield of finished parts. Greater process reliability is facilitated by the spacious layout between the clamping bushing and the clamping pyramid. Even during the clamping process, this design prevents virtually any dirt from getting onto the surfaces. This significantly cuts down the frequency of maintenance times for cleaning and lubrication. Overall, the mandrel has a clamping diameter range of 18 to 100 mm. The clamping areas of each size are designed to overlap. This has the advantage that users can choose from up to three mandrel sizes depending on the clamping diameter. The larger the mandrel is, the greater its stability and rigidity. Smaller mandrels may be able to handle more of the customers’ smaller workpieces. The aligned, segmented clamping bushings have a minimum concentricity of 0.01 mm and can even be supplied in a high-precision version.

Key advantages:

- I.D. clamping mandrel for clamping diameters of 18 to 100 mm

- Ideal for stringent manufacturing demands and process reliability

- Unique rigidity due to spacious layout of the clamping segments

- High transmissible torque and holding forces

- Contamination resistant due to hexagonal pyramid shape

- Concentricity < 0.01 mm also available in high precision version

Euro-Tech Corporation—#432272 (West Building)

Skiving has been around for a long time, but recent advances in technology have improved the speed and effectiveness of this gear-making process making it a more viable manufacturing option for gear producers. It has long been recognized that skiving would be a much more productive process than shaping for cutting many internal gears. Mytec Hydraclamp clamping tools are robust and rigid enough to minimize vibrations caused by the high spindle rpms and significant cutting forces generated by the new gear-skiving process.

Today’s demands also include clamping very thin parts for the robotic gearboxes (flex spline gearbox). Mytec Hydraclamp clamping tools are designed to clamp components the entire length of the clamping area. If the component is irregularly shaped, we clamp around it to achieve the highest accuracy. View the graphic as an example of a clamping situation with such a component used in the robotic gearbox. Note the external shape is irregular and the clamping area is very short. We designed a hydraulic chuck in combination with a changeable backstop and slotted collet. This gives the customer options to clamp different diameters and components with one hydraulic chuck. This hydraulic chuck is used to machine the spline in the “Gear Shaping” process on a Liebherr machine.

Mytec Hydraclamp continues to work closely with different machine producers to develop the perfect clamping solutions providing the highest runout accuracy, successive repeatability, and high clamping force applications. Euro-Tech Corporation is the exclusive North American distributor of the Mytec Hydraclamp product line.

Ringspann—#431968 (West Building)

Precision clamping fixtures for the complete machining of thin-walled lightweight components and high-precision internal clamping systems for use in gearing technology—just one reason why Ringspann has recently consolidated its position as an OEM supplier for machine tool manufacturers. Now the German company is surprising the industry with another innovation: high-performance diaphragm and taper sleeve clamping systems that are specially tailored to the requirements of the currently very popular power skiving process to produce high-precision external and internal gears.

As an alternative to gear hobbing, gear shaping, and broaching, skiving is enjoying renewed interest in the domain of gearing technology. Increasing quality and productivity demands in gear manufacturing are reviving the interest of machine tool manufacturers and e-drive producers in the manufacturing principle developed more than 100 years ago. Why? The process not only meets high standards of precision and accuracy but is also proving to be an extremely economical method for the cutting soft and hard machining of internal and external gears in the face of growing demands for batch size flexibility in series production. In addition, innovative leaps in control technology, high-performance machining and machine statics are fueling the entry of skiving into the production processes of gear manufacturers and gear suppliers. While other gearing processes must be used on special machines, power skiving can be used within the scope of complete machining in modern 5-axis centers. Accuracy losses due to multiple clamping can be reduced, as well as machining and set-up times.

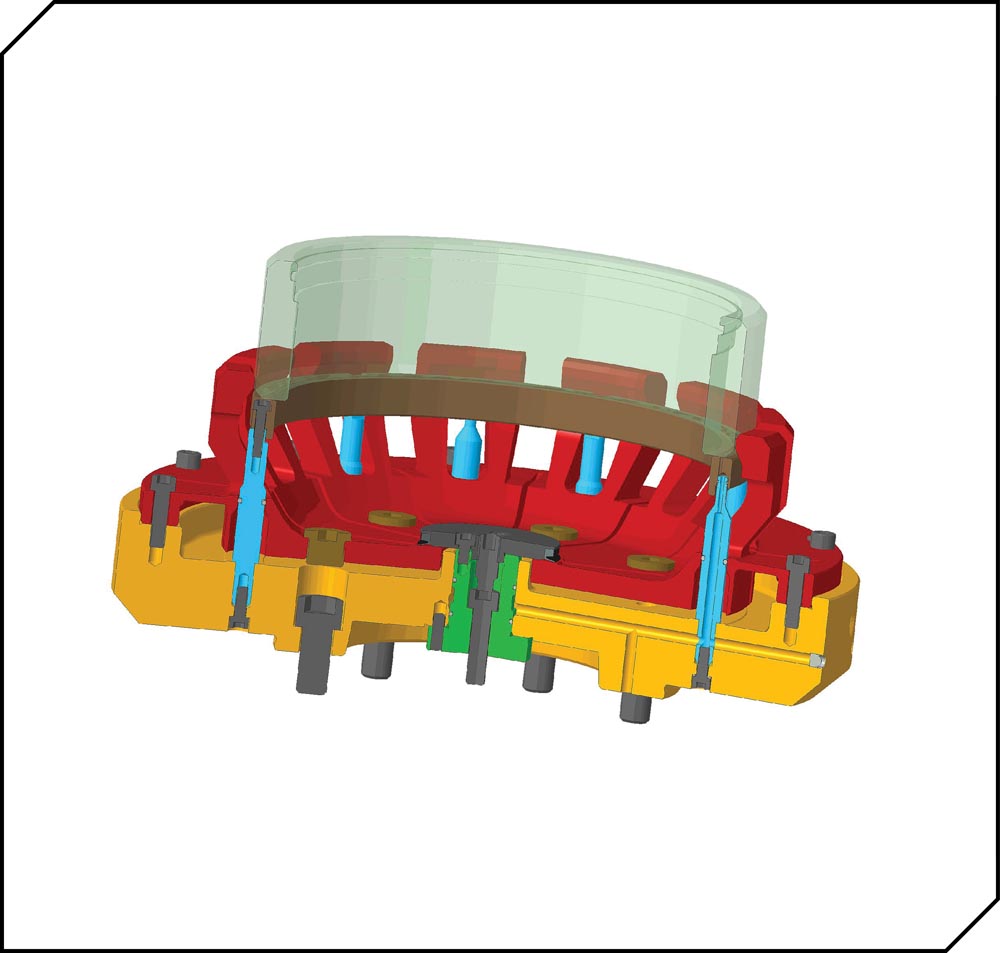

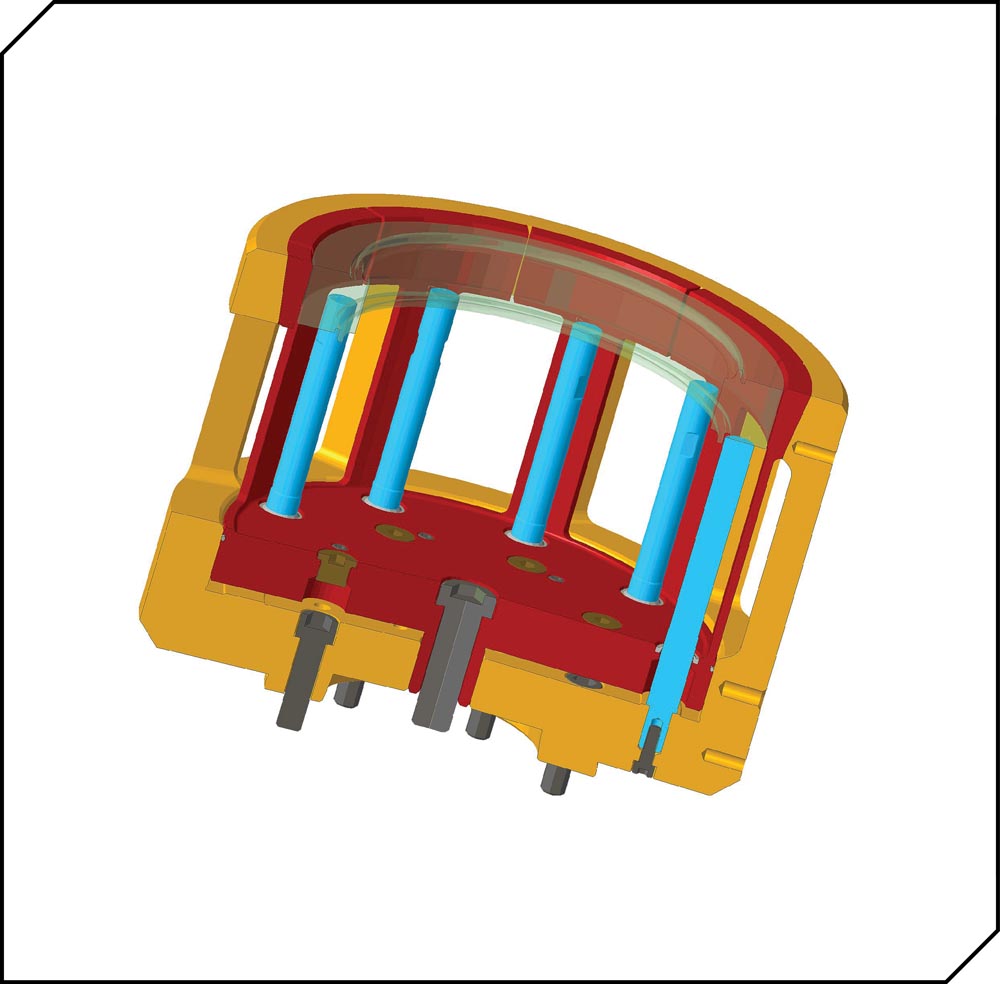

Deformation-free Clamping

However, the many advantages of skiving can only be fully realized in the practice of gearing technology if suitable clamping systems are used on the machines. This is because gear skiving is characterized by a precisely positioned skew between the driven workpiece and tool axes (axis intersection angle) and the synchronization of both speeds. The adjustment of the tool with a defined axial feed and the speed coupling of the workpiece and tool results in a relative movement with which the free space between the teeth is peeled into the material. In order for this to take place disturbance-free and with very short machining times (up to 50 percent faster than with gear hobbing), the clamping systems used here must be balanced for high speeds and guarantee problem-free chip removal. The diaphragm and taper sleeve clamping systems from Ringspann, which have been further developed for skiving, are precisely tailored to these requirements. They are particularly predestined for the internal gear cutting of thin-walled workpieces that must not deform under circumstances during machining—for example, weight-optimized toothed rings for planetary gears. In this application, for example, they replace conventional jaw chucks.

Open for Safe Chip Removal

“Both versions of Ringspann’s skiving clamping systems are based on fundamental functional principles that have proven themselves in gearing technology over a number of years,” says Joe Thompson, North American product manager of Workholding Solutions. Typical of their design is a relatively open construction, which enables rapid chip removal. Characteristic of the diaphragm clamping systems are a short overall length and a very uniform application of the clamping forces on the workpiece. They also offer the possibility of clamping on the shortest clamping surfaces. The key features of the taper sleeve clamping systems, on the other hand, are the large clamping depth and an impressive degree of rigidity. In both cases, the frictional connection is made via workpiece encompassing clamping elements, which can be quickly and easily exchanged during changeover. Ringspann supplies both versions ready for use, balanced and, if required, with air system control.

Added Benefit in the Process

The e-mobility boom in particular is causing a significant rise in demand for planetary gears. This is currently leading to growing interest in internal gears that can be manufactured very efficiently via skiving. The use of Ringspann’s diaphragm and taper sleeve clamping systems can help both gear suppliers and gear manufacturers to fully exploit the productivity and flexibility benefits of this process. Machine tool manufacturers, on the other hand, who offer skiving as part of complete multiaxis machining, can offer their customers Ringspann clamping systems as an added benefit within the scope of process integration.

Ringspann’s skiving clamping systems at a glance

Diaphragm clamping system for internal gears:

• Lightweight construction

• Power or manual operation

• Clamping with draw-down effect

• Air system control in contact bolt or backstop ring

• Open design optimizes chip removal

Taper sleeve clamping system for internal gears:

• Power operation

• Clamping with draw-down effect

• Air system control in contact bolt or bearing ring

• Open design optimizes chip removals