Revolutions

AGMA Offers Online Course on Involute Spline Design and Rating

This course will address both the geometry and rating of involute splines of various types

Read More

Metal Cutting Robots

Kadia Offers Deburring Robot Cells for Gear and General Machining Requirements

Read More

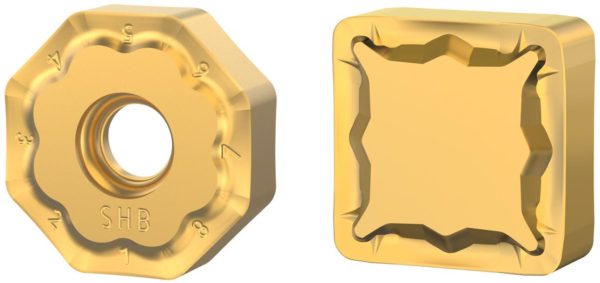

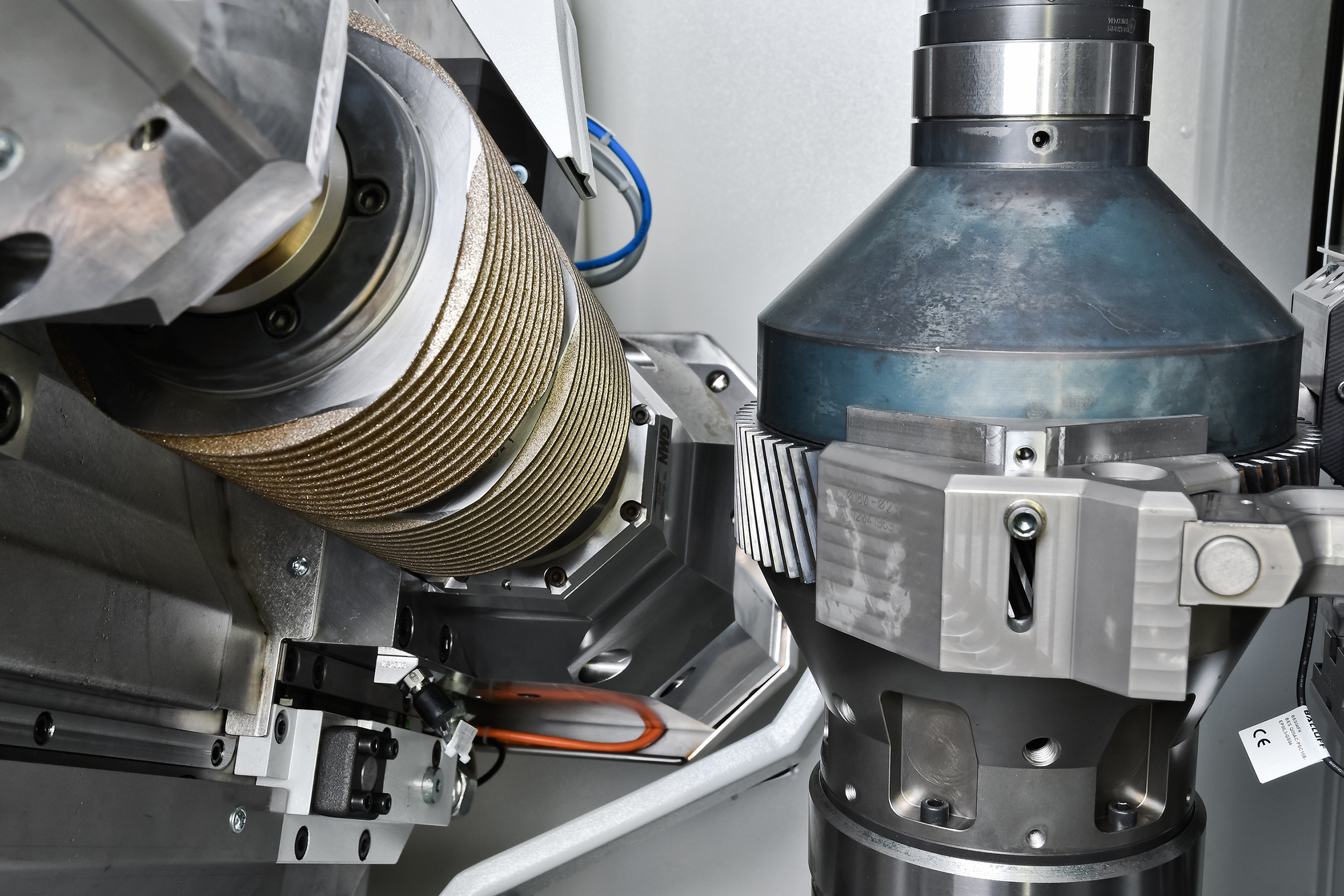

Recent Cutting Tools from Kennametal, Star SU, and Seco Offer Improved Tool Life and Precision

Reliable cutting tools are essential to production-process efficiency

Read More

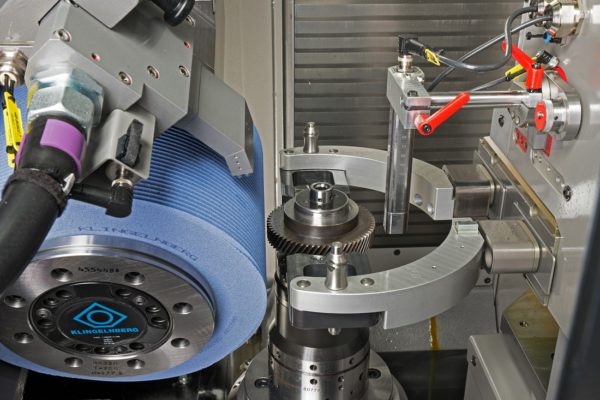

Quality Assurance Stakeholders Meet at Control 2022

Gleason and Klingelnberg unveil new quality assurance technologies

Read More

KISSsoft for Gear Manufacturing

Software integrates design, production, and metrology as a holistic process

Read More

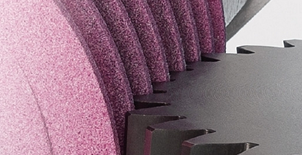

Liebherr Helps Customers Master E-mobility Gear Challenges

High quality demands puts high demands on integrated gear-production processes

Read More

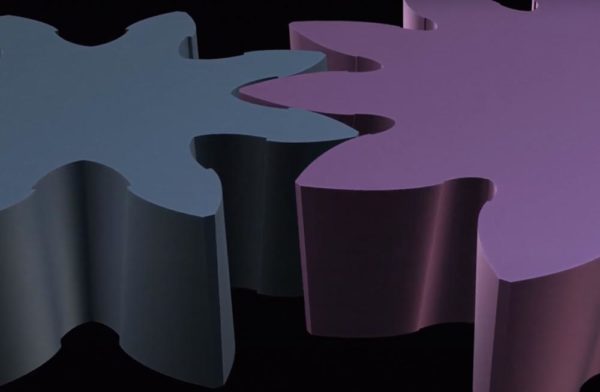

Solvay Specialty Polymers for High-Performance Plastic Gears

Thermoplastic injection-molded parts in automotive applications is growing and proving significant reductions in NVH issues

Read More

Recent Comments

With a sliding gear system, after disengaging, there...

Hi there, Nice Blog. Thanks for sharing the blog...

Not too dissimilar to the sliding gear system...

Request for details of this new advance methods...