As the gear and power transmission industries evolve, companies worldwide face a critical challenge: how to ensure the workforce is skilled, prepared, and ready to tackle increasingly complex manufacturing processes. From digital manufacturing and automation to generational turnover, the demand for technically proficient employees has never been higher. In response, the Motion + Power Technology Association (MPMA) redeveloped its Workforce Training Series, modernizing its most popular on-demand courses with updated content, high-quality media, and a flexible, self-paced delivery model.

This paper will review the development process, current research status, characteristics, functions, and measurement methods of TE. It will analyze the difficulties and core issues existing in the basic theory of TE, clarify the limitations and deficiencies of TE, and explore ways to overcome the shortcomings of TE.

.

A method to calculate pitch cones for hypoid gears using macrogeometry parameters—similar to non-offset bevel gears—while accounting for the added complexity of hypoid offset, tooling, and cutting technology is explored in this paper.

.

This work aims to demonstrate the potential benefit of applying nanocomposite coatings to gear teeth to reduce operating friction and wear by presenting tribological test data.

.

This study examines the implementation and experimental validation of state-of-the-art plastic worm gear design methods, focusing on the VDI 2736 guideline as the most comprehensive reference for load-carrying capacity calculations.

.

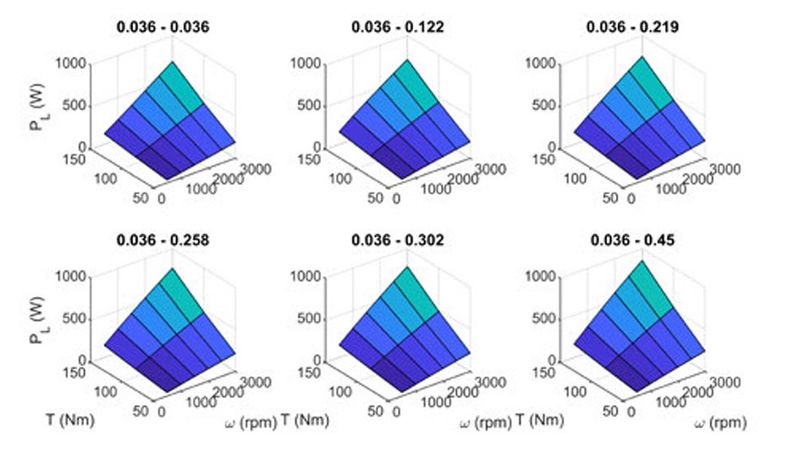

Mechanical power loss in gears is generated through sliding and rolling of the contact resulting in frictional work and elastic hysteresis generation of heat. This action is both a parasitic loss of energy from the drivetrain and a source of engineering costs to control system temperature to avoid heat-related failures of the gearbox components. Therefore, from both a cost and durability standpoint it is of great interest to minimize the frictional losses at the gear tooth contact interface.

For the research developed in this work, an existing simulation model of the generating gear grinding process based on a penetration calculation approach is used. Further, an extension of the model considering a realistic modeling of the grinding worm topography and the macro movements of the grinding worm during the process is presented. The result of the simulation is the microinteraction characteristics throughout

the grinding of the gear flank. In the end, the information about microinteraction characteristics obtained will be used for the calculation of force and energy in generating gear grinding.

A combination of international regulations and consumer expectations is driving the demand for reduced noise on all drivetrain components. Further demand is driven by the growing trend towards EVs and HEVs, where noise from ICE is intermittent or no longer present, and the contribution of transmission noise to overall vehicle noise becomes dominant.

Discover four diagnostic enhancement tools that move RX® endothermic gas atmosphere generator operations from preventative to predictive maintenance. Learn how monitoring dew point by retort, comparing equal flow, tracking tube performance, and measuring outlet temperatures prevent costly failures while ensuring consistent, high-quality carrier gas production.

Discover how SECO/WARWICK’s PIT-LPC furnace cuts cycle times by 60%, doubles throughput, and eliminates CO₂ emissions. Learn how vacuum carburizing redefines performance, safety, and sustainability in large-part heat treatment.

Spiroid Gearing delivers precision gearing for advanced mechanical systems engineered to handle extreme torque and complex motion requirements. With unique right-angle gear solutions, our technology enhances efficiency, reliability, and design flexibility. This empowers engineers to push boundaries in aerospace, defense, robotics, and industrial applications where performance and durability are non-negotiable.

CNC Gear Machine Tools: The Strategic Case for Re-controlling AND Re-building Versus New

Setting up an in-house heat treating operation allows businesses throughout many industries to harness this powerful technology and create better-quality metal parts. In this article, Surface Combustion discusses the biggest cost considerations involved in purchasing in-house heat treating technology and investment strategies to ensure you maximize your ROI.

Efficiency and process reliability are critical in modern manufacturing—and this is exactly where the EMAG VST 50 excels. A standout feature: the fully automated tool change. Thanks to an integrated robot, the tool change takes less than 90 seconds—all while production continues uninterrupted! The tool magazine ensures a smooth process: it swivels outward, the robot swiftly and precisely replacing the tool.

Visual Components announced its Omni Experience add-on virtual application with NVIDIA at the NVIDIA GTC global conference in Washington, D.C. Scheduled for release in early 2026, the integration enhances the Visual Components simulation platform with a new viewport built on NVIDIA Omniverse’s application programming interface (API).

Feb 10, 2026 - Feb 12, 2026

The AIoT World Expo (Fort Lauderdale, FL) is the premier event for exploring the convergence of Artificial Intelligence (AI) and the Internet of Things (IoT). This event serves as the gathering point for industry professionals to discover advancements, market opportunities, and understand the transformative power of AIoT across industries. Technologies include scalability, Edge, and AI data analytics, cloud solutions, machine learning (ML), and predictive analytics, cyber security and hybrid models.

Jan 20, 2026 - Jan 22, 2026

Mar 17, 2026 - Mar 19, 2026

Current Issue

Current Issue

Archives

Subscribe

Buyer's Guide

Cutting Tools Gear Blanks & Raw Material Gear Drives Gear Machines Gear Manufacturing Services Gears Grinding Wheels & Abrasive Tools Heat Treating Inspection Equipment Lubricants Machine Tools Resources Services Software Used Machinery Workholding & ToolholdingThe Gear Industry Buyers Guide is your complete directory of suppliers in the gear industry, including great companies like these.

VIEW ALL